How Can I Tell If a Load Cell Is a Quality One?

Not all load cells are created equal. The highest quality ones deliver reliable data, year after year, with proper care and regular maintenance. This isn’t happenstance. It is the result of meticulous planning, top-notch engineering, and an unwavering commitment to quality at every stage of manufacturing and testing. What sets this gold standard apart? This article answers this question to help you find the best quality strain gauge load cell.

Planning and Engineering: Crafting Quality

Meticulous planning and engineering are at the heart of every load cell in a series. These steps guarantee that each unit performs consistently within very tight tolerances. Top-tier manufacturers blend well-cataloged historical designs with new application and performance criteria to craft a concept product. They leverage finite element analysis (FEA) to theoretically test these prototypes well before the production line gets going. Furthermore, they iterate these concept products when necessary to develop a first-rate final design.

Design is only part of the planning phase. Every step of manufacturing, from tooling to personnel training, demands a well-documented roadmap and readiness checklist. Quality load cell manufacturers appreciate this. They rigorously document every step and decision from concept to final test, promoting transparency and accountability. They inspect all load cell raw materials for quality, certify that all machining components are in good working order, and ensure all technicians thoroughly understand their manufacturing tasks. They address issues well before the product line ramps up.

Manufacturing Quality: A Cut Above

Machining vs Stamping

When it comes to load cell quality, Computer Numerical Control (CNC) machining is the choice of the best manufacturers. With top-trained technicians and well-executed programming, CNC results in precise, repeatable cuts and bores. This guarantees that every element created is virtually identical.

Compare this with cheaper load cells. To save time and expense, some manufacturers will stamp planar load cells instead of machining them. This leaves internal stresses that, left alone, will produce high creep and hysteresis errors. Likewise, some single-point load cells have drilled, rather than machined, central dog-bone pockets. While this saves expense, it also compromises accuracy.

After machining, quality manufacturers will temper or anneal the load cell body to realign the element’s internal crystalline structure. This structure misaligns under the material stress caused by the machining process, compromising the load cell’s performance and longevity. Neglecting or improperly performing this step will produce an inferior product prone to failure under frequent-use or overload conditions. This process separates sub-par load cells from ones that stand the test of time.

Anti-Corrosion Treatments

Many load cells go to work in harsh environments that can accelerate corrosion, wear and tear. For this reason, after correcting for machining stresses, quality load cell manufacturers apply protective surface treatments like nickel plating to the load cell body. As with all other manufacturing steps, not all surface treatments are equal, if they exist at all. Quality manufacturers use clean treatment solutions and rigorously test sample units with specialized corrosion-test equipment.

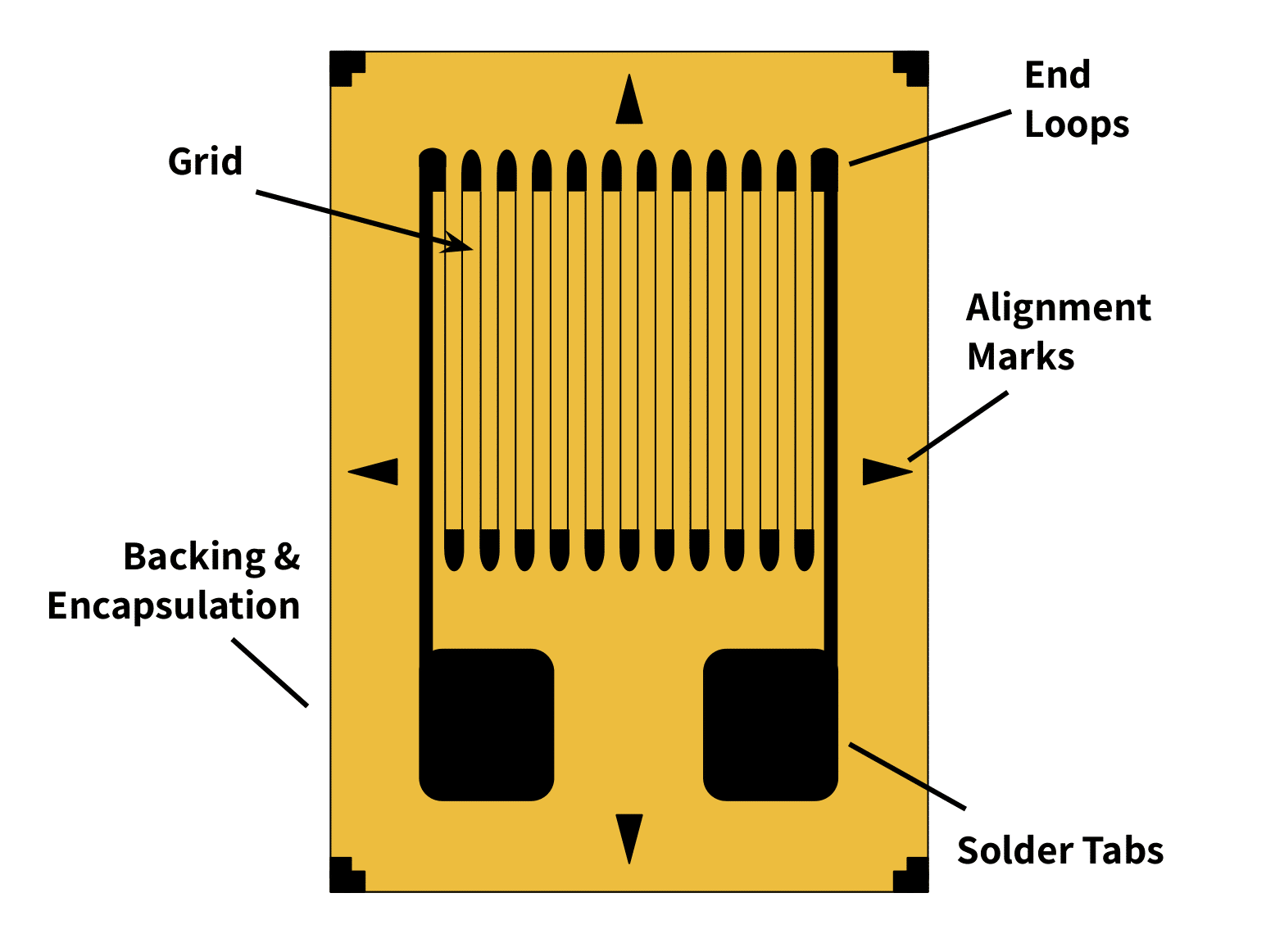

Strain Gauge Manufacturing

While the load cell body is important to quality, equal attention must be given to crafting the strain gauge itself. If not, this core transducer element will produce unreliable measurements. Its grid conductor must have uniform cross-section throughout to avoid any effects on resistance other than the applied strain. It must also have a quality backing that allows it to experience the full strain on the load cell body. The highest quality load cells contain strain gauges that meet these criteria.

Putting it Together: Quality Strain-Gauge Bonding and Soldering

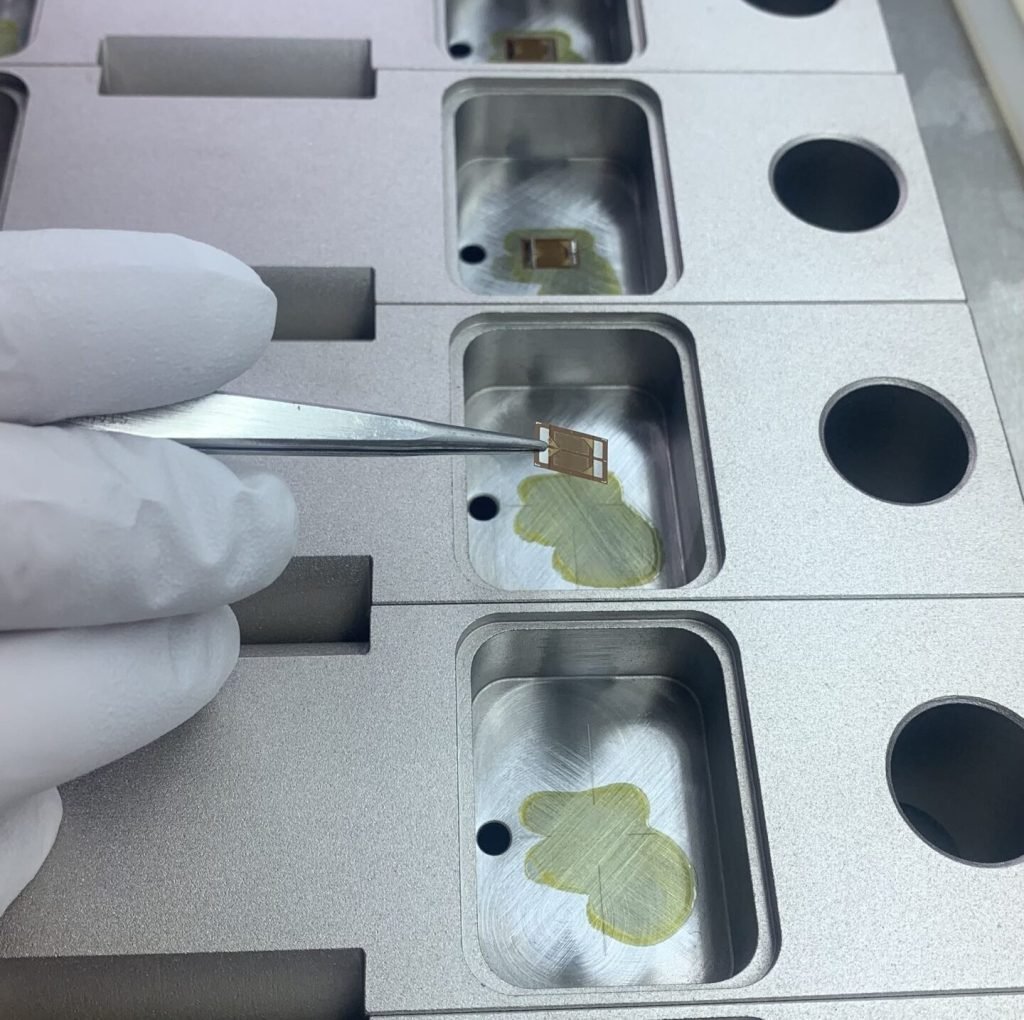

As we explained in The Versatile Strain Gauge Load Cell, the strain gauge is bonded to the load cell body at this point in the manufacturing process. This step is absolutely critical to a quality product. The best manufacturers perform this step in clean room environments to prevent contaminants from affecting the bond. Since often the gauges are intricately set with tweezers, these manufacturers have only the most skilled technicians perform this task. Likewise, the chosen bonding adhesive is vital to quality since it affects how well the load cell body and strain gauge function in unison to detect strain.

Once the strain gauges are in place, passive compensation resistors are soldered to them. These form the Wheatstone Bridge and adjust for temperature variations and other errors. Quality load cell manufacturers perform this step with repeatability, creating clean, uniform solder joints at appropriate temperatures to resist joint cracking or corrosion. Shortcuts here greatly affect the longevity of a load cell investment.

(Courtesy of ANYLOAD)

The Extra Step: Temperature Compensation

The highest quality load cells often undergo an additional step before the final sealing process to ensure they perform consistently even in extreme temperatures. This step monitors the load cell’s output during testing in specialized temperature chambers. If the load cell does not perform appropriately within its spec sheet’s temperature range, quality manufacturers will adjust the temperature compensation circuitry and retest the unit.

A weigh system designer should unequivocally verify that their chosen load cell has undergone this critical step if their system will be exposed to extreme temperatures.

Sealing the Deal: Ingress Protection

Once its manufacturing is complete, a load cell undergoes encapsulation to protect the electronics from moisture, debris, or vibration. Quality load cell manufacturers carefully pour a long-lasting potting compound into the electronics cavity that is virtually free of air bubbles since these can compromise the compound’s effectiveness. They then further seal the cavity with sealants or welds ensuring these do not leak (which could cause corrosion), nor alter the load direction through the strain gauge. Stainless steel load cells often have welded seals while alloy steel or aluminum cells typically have silicone seals.

Quantifying Quality: Unit Testing and Calibration

What ultimately sets a quality load cell apart from a mediocre one is final testing and calibration. Every quality load cell includes a calibration certificate that details the individual properties of that specific unit. Their manufacturers also test sample units for explosion resistance, overload limits, and similar extreme conditions. Once these load cells make their way to the marketplace, consumers can be confident they’re investing in the most thoroughly tested, trustworthy, and precise product.

Taking the Guesswork Out of Finding Quality Load Cells

Since load cells of vastly different quality can look very similar, finding a quality load cell can be challenging. This is why Tacuna Systems is committed to taking the guesswork out of the buying process. Every ANYLOAD and AmCells load cell we sell adheres to the strictest manufacturing processes outlined in this article. When you buy from our shop, you can rest assured that you are getting a quality product.

Want to learn more about the load cell manufacturing process? See this article by ANYLOAD on how they build their products to the strictest standards.