If you haven’t encountered the Tacuna Systems EMBSGB200 load cell amplifier, meet this well-traveled little device. It reliably performs on manufacturing floors, in ballistics testing labs, inside medical equipment, and even in farming technology for developing economies. The range of applications for this compact, affordable amplifier is broader than you might expect. In this article, we’ll share just a few of the remarkable, multi-disciplinary ways it’s advancing tech, and you may end up imagining even more uses of your own.

Green Energy: Testing Advanced Wave Power Generation Systems

The Tacuna Systems EMBSGB200 appears in many “green tech” applications, including this one from Azura Wave Technologies. Azura is one of the several companies making wave energy conversion technology commercially viable. As the name implies, this tech harnesses the power of ocean waves to generate electricity.

In 2017, they tested an innovative prototype using a 1:15 scale model. Unlike previous systems that harnessed vertical motion, their design could generate power from motion in all directions (vertically, forward and backward, and rotationally). They chose the Harold Alfond W2 Ocean Engineering Laboratory at the University of Maine since this laboratory can emulate various ocean depths, wave frequencies, and extreme conditions.

Azura’s system has a unique float or buoy at the surface connected to a rotating arm beneath. As this float moves, the rotating arm transfers energy to the Power Take-Off (PTO) system, which drives electrical generators. Control systems add resistance (damping) to the arm’s movement, optimizing its response to extreme wave conditions and maximizing energy capture.

Tests at the UMO laboratory gave Azura insight into how damping settings affected power generation efficiency. They also helped assess how the device would respond to extreme ocean conditions. Essential to these tests were torque sensor measurements on the system’s rotational arm, amplified using EMBSGB200 boards. These tests were foundational to the current Azura wave generation system design in the marketplace today.

You can read more about this research here: Azura Full-Scale Design: Test Plan for Wave Tank Testing.

Farming in Developing Areas: Making Modernization Viable

In many rural, underserved areas, farmers rely on draft animals to till and harvest their fields. Aside from being expensive, most commercial farm equipment is too unwieldy for small plots. Yet long-term, animal welfare can be financially burdensome.

To address this, a pair of researchers from MIT developed a compact “mini-tractor” prototype called the Bullkey. The design had big challenges, unachieved by any existing product. Though small, it had to offer a draft animal’s pulling force, even in difficult terrain. Its agility and price point needed to be similar to livestock. Finally, it required low maintenance and simple operation.

As with any prototype, a proof-of-concept study is vital. And that’s where the Tacuna Systems EMBSGB200 amplifier got involved. Already popular with MIT researchers for its compactness, cost, accuracy, and ease of use, our amplifier helped measure forces on the tractor’s tillage tool. Load cell data acquired in field testing proved that the experimental tractor had a higher drawbar pull per unit mass than conventional tractors, matching the peak pull of animals.

Figure 8 from the cited source showing various possible small tractor configurations. Configuration D was ultimately chosen.

Figure 7 from the cited source showing (A) an isometric view of the Bullkey with labeled soil-contacting components and (B) a free-body diagram with acting vector forces shown

The Bullkey’s draw power came from the innovative design that applied nearly all of the vehicle’s weight to the drive wheels. These were aligned single-file like a motorcycle, with the tillage tool affixed between both axles. This configuration allowed the Bullkey to navigate narrow crop rows while maintaining traction on muddy, uneven terrain—conditions that typically challenge lighter vehicles.

Beyond matching the draft animals’ performance, the Bullkey reduces physical strain on the farmer since it is operated while sitting. Initial farmer feedback was positive, indicating that a similar design may be in their commercial future.

Read more about this research at: Design of a Specialized Tractor to Replace Draft Animals in Small Farms, by Guillermo F. Diaz Lankenau and Amos G. Winter, V. More photos appear at this link.

Ballistics: Measuring Chamber Pressure and Testing Bulletproof Cladding

Sometimes, Tacuna Systems appears in enthusiast blogs. In this exchange from the EEVBlog Electronics Community Forum, contributors discuss how to capture the pressure in a shotgun chamber when the weapon fires. The consensus was that affixing a strain gauge to the chamber’s exterior could transduce the blast with the highest accuracy. However, the challenge was finding an amplifier with low enough noise and a high enough frequency range to handle the signal from the sudden peak pressure at the blast moment. According to one contributor, “I’ve settled upon a low noise Tacuna Systems EMBSGB200 Amplifier with the 930 kHz option by which to amplify the rapid voltage spike evolving across the Wheatstone Bridge, and a Rigol DHO802 Oscilloscope.”

This isn’t the only time our amplifier has been used in the field of ballistics. Research at the Federal University of Rio Grande do Sul in Brazil used the Tacuna Systems amplifier to study the characteristics of various ceramic composites under ballistic impact. The goal was to test the materials’ viability as protective cladding for aircraft and other vehicles.

Read more at these two links: ESTUDO DA CARACTERIZAÇÃO DINÂMICA DE MATERIAIS SUBMETIDOS A ALTAS TAXAS DE DEFORMAÇÃO UTILIZANDO A BARRA DE HOPKINSON by Gustavo Fontoura de Aguiar and UM ESTUDO DA DISSIPAÇÃO DE ENERGIA EM MATERIAIS CERÂMICOS SUBMETIDO A IMPACTO UTILIZANDO A BARRA DE HOPKINSON by Guilherme Augusto Jacometo.

Advancing Medicine: Better Muscle Response Detection

Mechanomyography (MMG) is a big word for a sensor technology that records really small muscle movements. Unlike the alternative, electromyography (EMG), which detects the body’s electrical signals, MMG senses mechanical muscle contractions. This makes it less susceptible to electrical interference, a major advantage in medical environments where myriad electrical equipment distorts signals. Although MMG had fallen out of favor for a time vs. EMG, its non-invasive nature and low distortion have spurred renewed interest in fields like prosthetics, physical rehabilitation, and muscle research.

An article published in the Aug 2023 issue of Anesthesiology magazine describes the prototyping of a more modern mechanomyography. The testing measured subtle thumb movements in response to ulnar nerve stimulation. To prove its viability, the creators compared measurements from their new device to those of a circa-1970s version. Our EMBSGB200 amplifier earned a place in the data collection system for its measurement range, small size, and precision.

From the source document, a depiction of the experiment setup

Testing from the new device produced similar measurement curves as the historical device. However, the updated technology had improved precision, resolution, and sensitivity compared to the archival mechanomyography system. These findings position MMG as a promising option for anesthesiology, where real-time muscle monitoring is vital for assessing neuromuscular blockade. Moreover, MMG could become a staple in prosthetic development, allowing devices to adapt more naturally to a user’s muscle signals.

You can read more about this research by clicking here: Comparison of a Modern Digital Mechanomyograph to a Mechanomyograph Utilizing an Archival Grass Force Transducer, Kelly E. Michaelsen, M.D., Ph.D.; Srdjan Jelacic, M.D., F.A.S.E.; Sharon T. Nguyen, B.S.; Kishanee J. Haththotuwegama, B.S.; Kei Togashi, M.D., M.P.H.; Andrew Bowdle, M.D., Ph.D., F.A.S.E.

Manufacturing: Making Precision Assembly Even More Precise

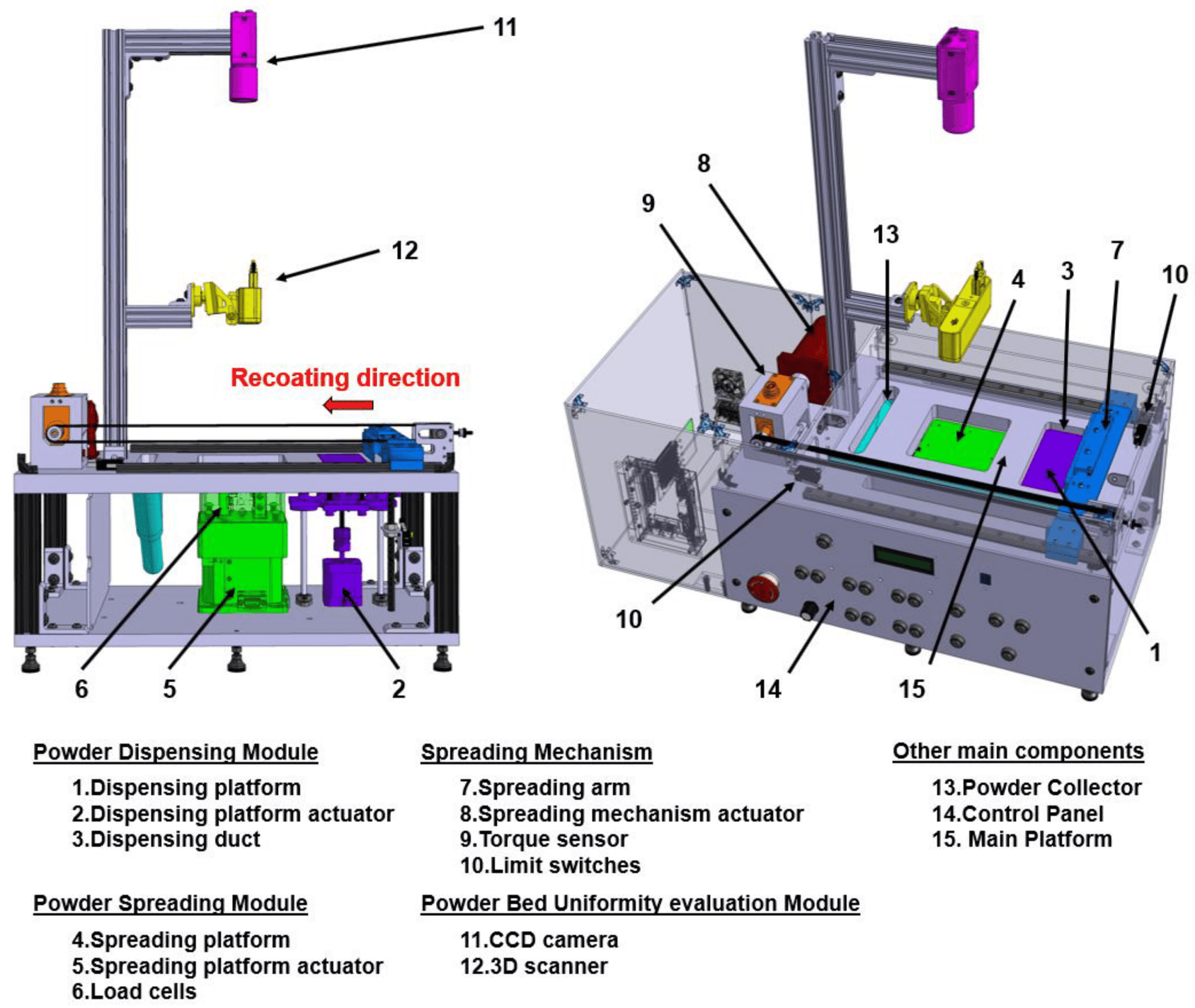

If you’re familiar with Powder Bed Additive Manufacturing (PBAM), you know it builds high-precision parts by spreading thin layers of powdered material (polymers, metals, or ceramics), then fusing them. Achieving consistent quality in PBAM hinges on optimizing several variables: powder type, particle size, layer thickness, and spreading technique. Yet, how these factors interact hasn’t always been fully understood.

Researchers at the University of Montreal sought to change that. They built a custom test rig (pictured) to study how spreading speed and powder deposit thickness affect layer uniformity and density—two key factors in the final product’s structural quality. The device’s platform mimicked the part-building surface of a real PBAM machine.

Their initial study aimed to prove the device could reliably detect the impact of the two mentioned mechanical settings. If successful, it would help uncover ideal combinations of powder properties and machine parameters, increasing PBAM efficiency without sacrificing performance.

Detail of the spreading module depicted in green in the first test device image

For this validation step, the researchers kept the powder type and particle size constant. Varying application speed and thickness, they measured each deposited layer’s weight using two 300g ANYLOAD 108AA load cells paired with our EMBSGB200 amplifier. They chose the EMBSGB200 in part for its simplicity, having factory-preset gain settings.

The results? The device achieved its goals, revealing how changes in spreading techniques alter powder behavior. Future experiments will expand on this work by testing how intrinsic powder characteristics (such as granule shapes and size distributions) further influence layer quality. And these findings will bring PBAM one step closer to faster, more precise, and more reliable assemblies.

Learn more at: A Novel Apparatus for the Simulation of Powder Spreading Procedures in Powder-Bed-Based Additive Manufacturing Processes: Design, Calibration, and Case Study by Salah Eddine Brika and Vladimir Brailovski.

All Technologies: Amplifying the Future

As the examples here show, the Tacuna Systems EMBSGB200 amplifier is more than a component. It’s a driving force behind innovation across diverse fields. From green tech and manufacturing to ballistics and healthcare, this compact, cost-effective amplifier brings high precision, low noise, and adaptability to the forefront of both controlled labs and cutting-edge industries. Its versatility and ease of use have made it one of the most widely used amplifiers in transformative tech, underscoring Tacuna Systems’ commitment to pushing the boundaries of possibility.

If you’ve used the EMBSGB200 in a unique application and are willing to share your story, let us know!