Cal Poly Rocketry Test Stand Gets off the Ground with Tacuna Systems

Throughout our history, Tacuna Systems has had a close relationship with teaching institutions. We love when they reach out to us to help support their lab work. And when we have permission, we love sharing summaries of the research we encounter. This article tells about one such encounter with the Space Systems Club at the California Polytechnic State University (Cal Poly).

The Cal Poly Space Systems Club

The club gives students of all majors hands-on experience in all areas of rocket design. Much like in the professional world, the club is subdivided into teams. An aerodynamics team creates physical designs that allow each rocket to reach its required height while minimizing drag. They work closely with a structures team that balances minimal structural weight with structural strength to withstand launch and recovery forces. The avionics team designs efficient power delivery to all rocket systems while likewise minimizing its impact on rocket weight. Propulsion team members design the engines that receive that power.

Like other space agencies, the club conducts experiments in their rocket payload. For this purpose, a payload team specializes in designing and integrating these experiments with the craft’s other design elements. Because rockets need to safely reach the ground, a recovery team designs the required parachutes, streamers, pressure vessels and cut-off valves. The club’s ground support team engineers all non-rocket systems including communications, testing, and other support hardware. Putting it all together, the systems team makes sure all rocket components work together effectively and consistently. And finally, a business and marketing team handles publicity and development.

The Rocketry Test Stand Frame

This academic year, the Space Systems club launched its Dulcimer project, Cal Poly’s first club-developed liquid engine. To safely test this bi-propellant rocket engine, the club needed a rocketry test stand. The stand would have to safely support the operating engine (up to 600 lbf or 2669 newtons of force), supply its fuel, and measure the engine thrust. The stand also had to be portable, measure pressure data in the fuel feed lines and run tanks, and record temperature data in the feed system and rocket engine itself.

The first order of business was to choose a budget-friendly, lightweight (for portability) structural material that would withstand the elements. The team settled on an extruded aluminum frame that met its design criteria.

Next, the team developed a frame design that would withstand non-axial forces and that could be easily expanded or modified to accommodate multiple engine designs. The team chose a vertical engine test configuration for improved safety. They conducted finite element analysis on the frame with a maximum upward force of 600lbf to ensure their design would theoretically withstand all generated forces.

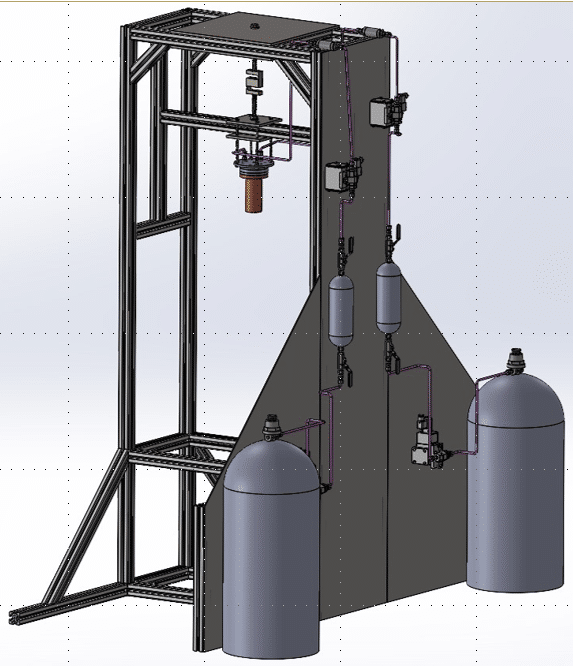

No test stand would be complete without safety elements, so the team included a blast plate and flame diverter in the design. The blast plate would shield the fuel tanks from the engine exhaust heat and provide a physical barrier in case of engine failure. The flame diverter would redirect engine exhaust away from sensitive equipment. Figure 1 shows the concept.

The Fuel Feed Systems

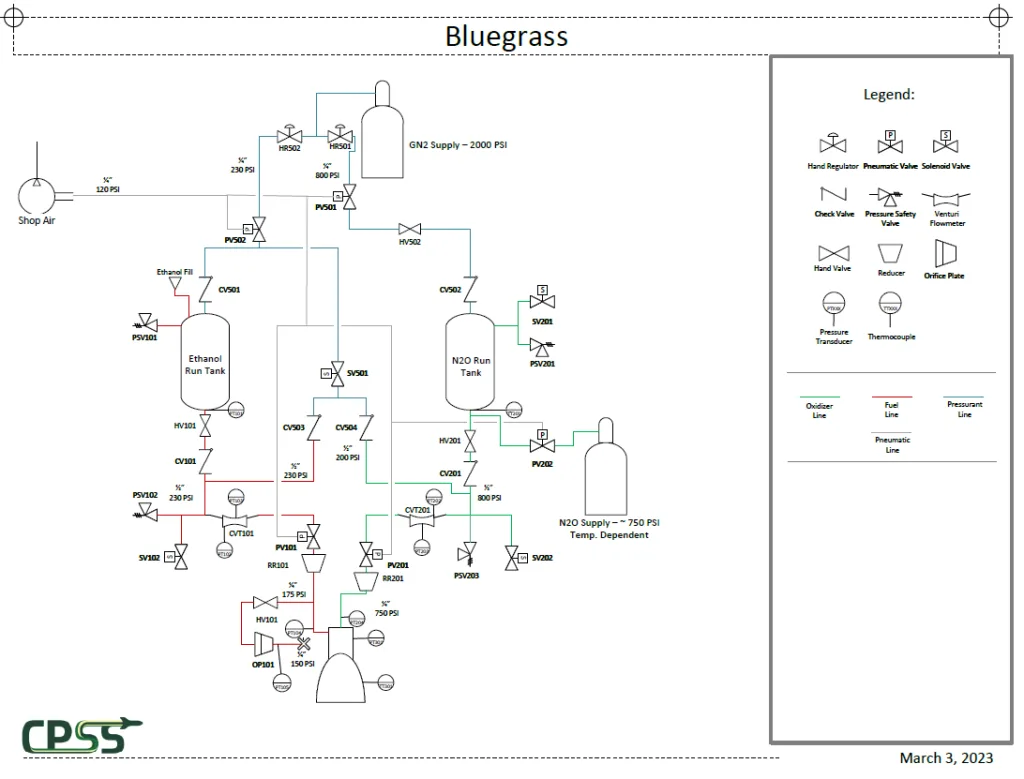

The rocketry test stand’s initial fuel system was made specific to the Dulcimer project. Its design will supply ethanol as fuel and nitrous oxide as an oxidizer to the rocket engine. A third line will deliver gaseous nitrogen to pressurize the ethanol. The team’s objective was to deliver a steady supply of fuel with a system of regulators, controlled valves, and safety valves. The system has included safety valves to prevent excessive pressure in the lines and tanks. Figure 2 shows the club’s CAD drawing of this design (used with permission).

The Sensors and Data Acquisition

Sensors throughout the test stand will not just measure the engine thrust. They will also monitor fuel pressure and temperature as well as engine temperature throughout testing.

Tacuna Systems became a part of the Dulcimer project since the team needed an S-type load cell for engine thrust measurement. (See top of Figure 1. ) Because of their tight timeframe and long wait times from other suppliers, the team chose an AmCells STL-50lb S-type load cell acquired from Tacuna Systems.

All sensors will connect to a National Systems data acquisition device (DAC). This will, in turn, feed into LabView software for real-time monitoring and data collection.

Outcomes

As of March 2023, the Space Systems Club has begun building its rocketry test stand. If all goes according to plan, they will begin testing their bi-propellant engine by the end of May. We wish the team well and hope to have an update when the test stand is operational.