An Overview of Terminal Blocks

What is a terminal block?

A terminal block is a type of wiring connector encased in a rigid, insulated housing, typically made of plastic. It features one or more circuit connection points, each designed to connect a single input wire to a single output wire. Individual connection points have two cavities to insert these two wires, a clamping mechanism to secure each wire, and a conducting strip between the two clamps to establish the connection. Some terminal blocks may instead have only a cavity for an input wire and a hardwired output pin.

Terminal blocks complete circuits between two bare wire ends, similar to twisting wires together and covering them with insulating tape or a wire cap. However, aside from safety, terminal blocks have distinct advantages. They organize circuits better as they neatly mount to panels or boards, and come in colors to help distinguish or group connections. They also make circuit maintenance easier since they enable easy replacement of faulty devices without disturbing the rest of the circuit.

Types of Electrical Terminal Blocks

Terminal blocks usually fall into categories according to what they mount to, how many connections they establish, how they secure the attached wires, and their electrical specifications.

Terminal Block Mounting Configurations

PCB Mount

These terminal blocks attach to a printed circuit board (PCB). One side secures a bare wire with a clamp or screw, while the other side has a metal peg soldered to the PCB, making only one side of the connection semi-permanent. They can establish single, dual, or multiple connections.

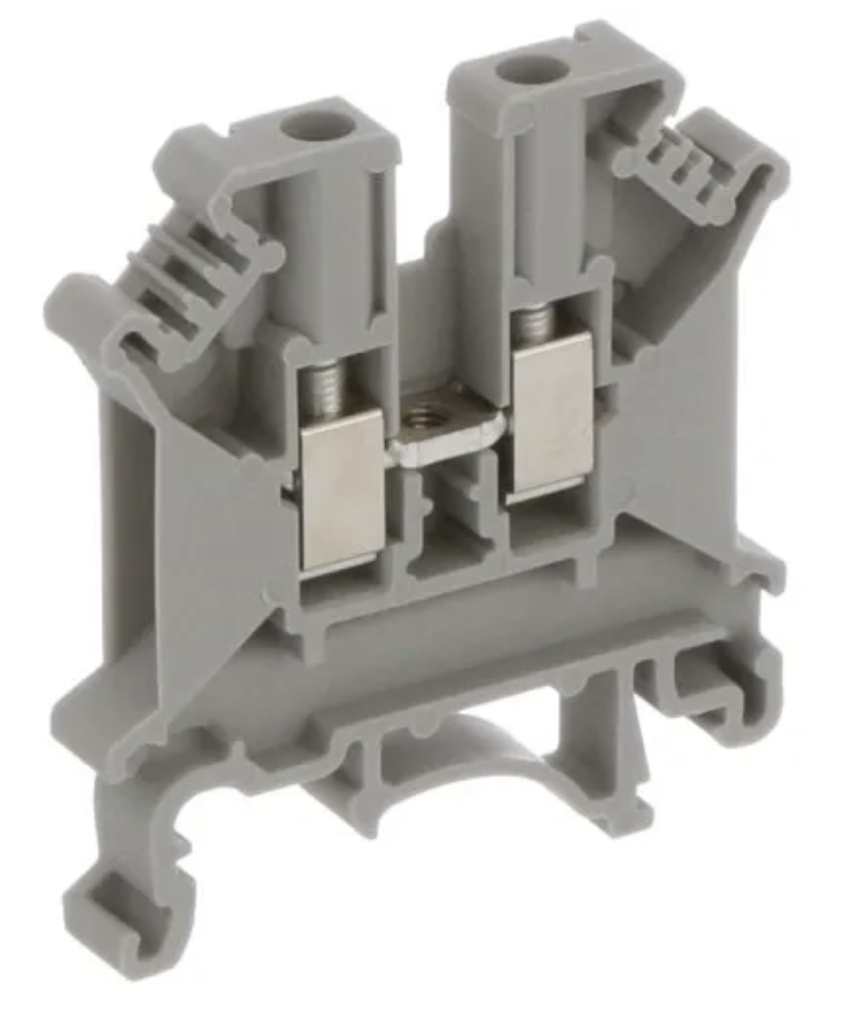

Pass-through/DIN Rail

As the name implies, these terminal blocks have a housing shaped for mounting on a DIN rail. Like the PCB-mount type, they may have single, dual, or multiple levels, each level connecting one input to one output (hence, “pass-through”).

DIN rail terminal block housings typically have slots for each input opposite the slots for outputs. A clamp or screw secures each bare wire end within each slot.

Barrier Strips

Designed for high-vibration environments, these have multiple connections in a single, flat row with rigid, insulating barriers between individual circuits to prevent arcing or shorts. Barrier strips hold each wire securely in place with a screw through a spade or ring terminal on each wire end. The highly insulated connections make this terminal block ideal for high-voltage applications.

Wire Clamping Types Within Terminal Block Housing

The wire clamp in a terminal block securely holds each inserted wire. The different designs account for wire size and type, vibration and other forces that may loosen connections, and ease of connecting/disconnecting input/output devices.

Screw Clips

Screw clips are among the more common wire clamping mechanisms in a terminal block. With these, the exposed wire end is held in place with a thin metal strip or collar that compresses it by turning a screw.

This clip is most often used with stranded wire. Proper installation ensures a secure connection.

Spring Clips/Push-in

Ideal for solid wire, push-in clamps secure the wire with spring compression rather than a screw, much like a clothespin. The clamp pries open to receive the wire end with the pressure of the inserted wire. Since the spring tension can degrade with corrosion, connections should be protected from the elements and checked periodically. However, they are easier to use than screw clips.

Push Button

These operate like push-in clamps, but the spring clamp opens with the push of a button at the top of the housing and secures the connection by releasing the button. Therefore, these can be used with stranded wire.

Connection Structures in Terminal Blocks

These structures determine the number of circuits within each block and whether they are point to point or point to multi-point.

Single-level pass-through

As the name implies, these terminal blocks have only one circuit connection. They connect one input wire to one output wire.

Dual-level pass-through

Designed to save space, these terminal blocks have two separate circuit connections, one stacked upon another.

Multi-level pass-through

As the name implies, these devices connect multiple, independent circuits within one housing. Tacuna Systems has two such options in its catalog, a 6-pin PCB terminal block and a 9-pin PCB terminal block.

Ground Terminal blocks

Ground terminal blocks are similar in structure to single pass-through blocks, but the internal clamps connect the wires to an electrical ground.

Fused Terminal Blocks

Fused terminal blocks replace the metal connection between input and output terminals with a fuse for overcurrent protection.

Power Distribution Terminal Blocks

Unlike most terminal blocks, power distribution terminal blocks have one large gauge input connection point and multiple, smaller gauge outputs.

Specifications to Consider When Choosing a Terminal Block

Beyond mounting configurations, clamp types and internal structures, the specifications below will help determine if a terminal block is right for your application.

Pole Count

Pole count refers to the number of individual circuits that pass through the terminal block. When thinking of pole count, consider whether the application will need future circuits, and plan for spare poles.

Pitch

Pitch is the physical space between circuits from clamp center to clamp center. It is usually measured in millimeters. The greater the pitch, the greater the protection from arcing.

Wire size and type

As mentioned earlier, some wire clamps are best suited for stranded wire while others best accommodate solid wire. The clearance within the clamps influences the wire gauge that the terminal block can accommodate, along with its voltage and amperage ratings.

Amperage rating

Like all conductors, the terminal block’s amperage rating is based on its terminals’ conductivity, cross-sectional area, and heat generation. Generally, the terminal block should have an amperage rating of 150% of the highest current expected.

Voltage rating

A terminal block’s voltage rating depends on the housing’s dielectric strength and the pitch. This rating should exceed the circuit’s maximum voltage plus any possible surges.

Mechanical structure

Mechanical structure refers to the orientation of the terminal block’s inputs relative to the outputs. The most common orientations are linear, 90 degrees, or 45 degrees.

Safety/flammability rating

Terminal blocks generally give a safety or flammability rating that complies with UL (North America) or IEC (International) standards. A terminal block’s ratings should always exceed the most extreme conditions that a circuit may encounter in service.

Tacuna Systems Terminal Blocks

As mentioned earlier, Tacuna Systems offers two PCB terminal blocks, a 6- and a 9-pole version. These are ideal for circuits that use our EMBSGB200 amplifier. Specifications can be found on the product pages.