Improving the Safety of Scaffolding Using Sensors

According to the Occupational Safety and Health Administration (OSHA), over 2 million people work on scaffolds. However, despite hours of training per OSHA regulatory practices, there are approximately 50 scaffold-related deaths and 4,500 injuries every year[1]. Of those, about 75% are due to human error[2]. The other 25% of scaffolding accidents are due to external conditions such as strong wind forces, earthquake loads, and other natural disasters. Clearly there is room for improving the safety of scaffolding.

Yet even the best-trained construction supervisor can find it difficult to monitor all personnel. And natural forces are often unexpected. This is where IoT technology and research come in, to bring advancements in scaffold monitoring. Termed “smart scaffolding,” this technology combines the use of wireless force/strain sensors with computer software and machine learning algorithms to automate monitoring and improve safety.

A Brief Background on Scaffolding

A scaffold is defined as “a temporary structure used to support people and material during construction or maintenance of buildings and other large structures.”[2] Its main purpose is to assure that work can be done safely at heights. Much of scaffold safety depends on best-practices implementation, taking into account the following factors:

- Designs

- Fabrication materials

- Assembly

All three greatly affect the scaffold’s stability and determine its likelihood of failure.

Designs

Generally, there are two main types of scaffold designs:

- Suspended (for example, window washing on high rises)

- Supported type (for example, most forms of building construction)

Some researchers [5] have classified scaffolds into access scaffolds and support scaffolds. The former are attached to a permanent structure for increased stability, while the latter have adjustable extensions with U-head screw jacks.

A scaffold’s design is typically based on both the application and on standards for column spacing and height of each level. These latter two parameters greatly affect the structure’s load bearing capacity; this relationship is quantified using known mathematical formulas. Some of the scaffold’s major components also contribute to its load bearing capacity, namely the supports, the anchors, and guard rails[4].

Furthermore, industry standards bodies establish guidelines for scaffold construction in different applications. These are important to know and follow when designing a scaffold structure. In the United States, the Occupational Safety and Health Administration (OSHA) determines compliance with standards set forth in Title 29 of the Code Federal Regulations (CFR) Part 1926, Subpart L.

Fabrication Materials

Scaffolds, depending on their applications, are a modular assembly of cylindrical pipes. The materials composing them are generally timber, bamboo, steel, and aluminum. The bearing capacity of each material given the desired shape and length of structural member clearly is important to the application. It can be calculated specific to the structure design using straightforward mathematical equations[3].

Each of these materials has its own advantages; however aluminum is preferable and is lighter than the rest.

Assembly

Once designed, the next step in implementing a scaffold is the assembly. Best practices dictate that an expert supervise this step.

Monitoring Scaffolds With Sensors to Improve Safety

As stated earlier, even when implementing best practices for design, materials and assembly, scaffolds may experience dangerous failures. Most are due to unexpected environmental forces and overloading. Advancements in load cell technology, particularly wireless load cells, have made continuous monitoring of these structures possible. This, and advances in IoT technology (the Internet of Things: see The IoT and Sensors: A Quick Overview) such as better communications protocols, power consumption, and applications, make smart scaffolding feasible. A well-designed smart scaffolding system can issue life-saving warnings to workers when loads exceed the structure’s capacity.

The Safety Parameters of Interest

“Smart scaffolding” measures specific parameters, chosen for their degree of influence on any potential collapse of the structure. Research suggests that the following parameters are generally most relevant to improving scaffold safety:

- slab settlement,

- overall vertical displacement,

- overall horizontal displacement,

- axial forces acting on the columns,

- column tilting angle, and

- wall anchors/ties/braces removal or failure.

Sensors integrated into the structure provide feedback to the monitoring system. This automates the inspection process by digitizing the criteria of a typical physical assessment by a site supervisor.

Sensor Technologies Used For Smart Scaffold Monitoring

For scaffold monitoring, strain gauge load sensors are most common. (See [6] for an explanation of these sensors.) The strain gauge produces an electrical signal once any of its dimensional parameters (length and cross-sectional area) is changed physically. Therefore, when placed in key locations in a scaffold structure, they provide a response to each of the key parameters mentioned above.

To quantify these parameters, the following sensors are advised:

- Displacement sensors for monitoring slab settlements and displacements

- Force/load sensors for detecting axial forces acting on the columns

- Angle sensors, which operate like an axial force sensor but are mounted to record angular displacements

- Fracture wire or tension link load cells to detect fracture/removal of anchors

Furthermore, according to research, much of the structural response of a scaffold system is a function of its overall strain distribution[7]. This further motivates for the widespread use of various strain sensors to detect impending scaffold failures.

Mounting the Strain Sensors

To properly mount the sensors, engineers must determine the exact locations of greatest response for each desired physical parameter of the scaffold system. For example, the movement of the slab causes a displacement between the scaffold’s horizontal beams and vertical columns. To monitor this parameter, a strain gauge is mounted between these structural members. A shift in the slab would cause a physical displacement of the gauge, generating the desired signal. Likewise, to monitor the system’s angular displacement, a strain sensor can be installed at the topmost story. This level is generally the weakest part of the structure. It will therefore respond to any tilting movement of the columns. The strain sensor will in turn detect this response.

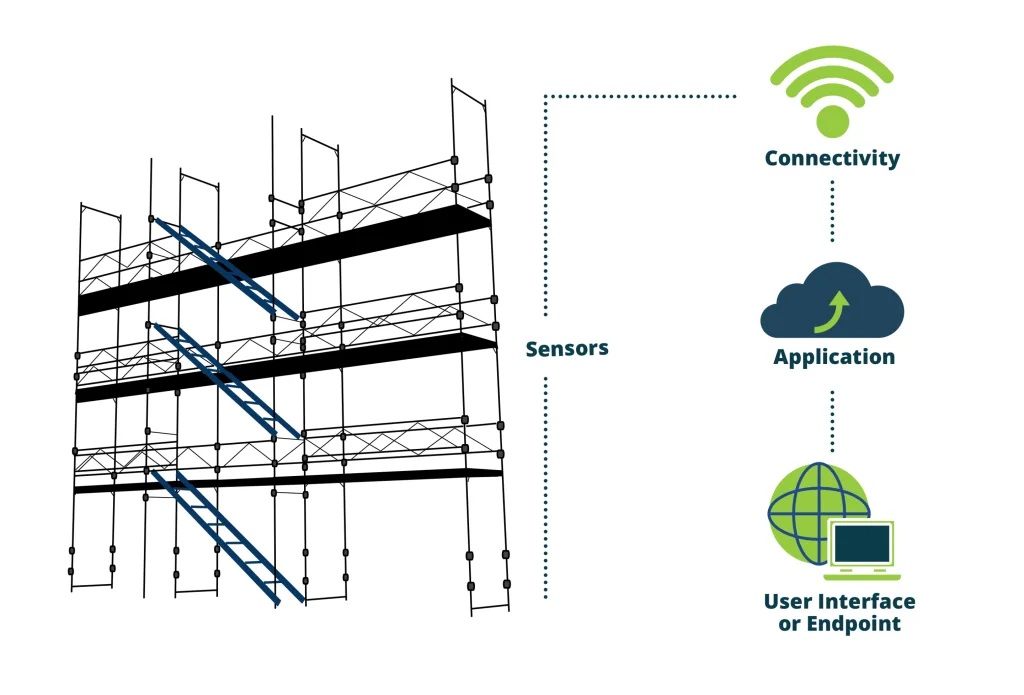

Connecting the Strain Sensors to the Monitoring Application

To complete the monitoring system, the sensor output must communicate with an application that interprets the data and initiates safety procedures when necessary (as illustrated in Figure 1 above). This application is most often in a remote, central location. As described in The IoT and Sensors: A Quick Overview, this scenario lends itself to wireless communication technology. Wireless communication also eliminates the need for wiring that adds both to the safety concerns of the scaffold system design, and cost.

Analyzing the Sensor Data and Model Generation

Through continuous, active monitoring, the sensors create a huge field of data describing the response of the scaffold system. Monitoring applications then analyze this data to present actionable information to end users. For example, analyzed data can appear graphically on a user interface either on-site or in a central monitoring location in real time. Or it can trigger alarms or warnings to workers at the scaffolding site via wireless communication whenever it senses a potential failure.

This raw data can also improve the monitoring process. Using current technology trends in data science, researchers have applied machine learning (ML) tools to analyze, study, and classify the data pool from these sensors. This has enabled the generation of set points or thresholds to predict system failures more accurately. Moreover, current research has advanced this concept by generating finite-element 3D models of scaffold systems using software tools such as MATLAB, GMNAF, COMSOL Multiphysics, and NIDA. These models are used to study the load-bearing capacity of various designs. The real sensor data analyzed by the ML algorithms can be fed back to the computer models of the scaffold[7] to update and fine-tune these designs.

Conclusions

A lot of research surrounding improving scaffold safety remains. Its goals include reducing the time to deploy monitoring systems, developing precise scaffold models for finite-element analysis software, and improving sensor unit calibration. A major challenge for these deployments has been the power supply for the sensor units. (In fact this issue is typical of many Internet of Things (IoT) applications – the battery life of continuously monitoring sensors.) Advances will need to address how to efficiently consume and supply power to sensors while assuring the continuous active monitoring of the scaffold structure. Developments in IoT technologies will help solve this problem.

Despite current limitations, incorporating sensors remains one of the best ways to improve scaffold safety and mitigate the financial and personnel costs of system failures.

References

[1]

Park, Jeewoong & Cho, Chunhee & Kim, Kyungki & Sakhakarmi, Sayan., “Scaffolding Modelling for Real-Time Monitoring using a Strain Sensing Approach,” in 35th International Symposium on Automation and Robotics in Construction (ISARC 2018), Berlin, Germany, 2018.

[2]

Christopher Ullrich, “Implementation of sensor technology in scaffolding- An application of technological brokering and smart product design,” Centre for Entrepreneurship, University of Oslo, 2016.

[3]

Su, Jian & Li, Jieming & Tan, Lingsheng & Huang, Xiaodan., “Development of the IoT-based Monitoring System for Scaffold Shoring System of Concrete Formwork,” in MATEC Web of Conferences, 2018.

[4]

Pieńko, Michał & Robak, Aleksander & Błazik-Borowa, Ewa & Szer, J., “Safety Conditions Analysis of Scaffolding on Construction Sites,” International Journal of Civil, Environmental, Structural, Construction and Architectural Engineering., pp. 72-77, 2018.

[5]

T. Chandrangsu, K.J.R. Rasmussen, “Review of past research on scaffold systems,” University of Sydney, Department of Civil Engineering, 2009

[6]

An Overview of Load Cells, Tacuna Systems

[7]

Park, Jeewoong & Cho, Chunhee & Cho, Yong & Kim, Kyungki., “Data-Driven Monitoring System for Preventing the Collapse of Scaffolding Structures,” Journal of Construction Engineering and Management, 2018.

[8]

ANSI Blog: Integrating Load Sensors into Scaffolding for Improving Safety https://blog.ansi.org/?p=160779