The IoT and Sensors: A Quick Overview

If you’ve ever entered Tomorrowland at Disney World, you’ve seen the Carousel of Progress. Inside is an animatronic show that debuted at the 1964 World’s Fair, moving to its current location in the 1970s. It follows the story of a family as their world evolves through technology. This family traverses several decades of advances, from manual to electric appliances, music recordings and the like. In the final scene, a “smart” oven overhears a video game score, interprets it as a temperature setting and burns the Christmas turkey. Back in 1964, this vision of the future where appliances could respond to voice commands seemed nearly impossible. And yet here we sit, several decades into the 21st century, surrounded by these “future” smart technologies.

Today’s world has moved beyond this animatronic future into one where devices don’t just respond to needs, but predict them. This is the world of IoT, or Internet of Things. The Internet of Things is simply a concept – one where all the devices with which we interact connect wirelessly to the internet to improve their efficiency, safety, or user experience. These devices can be consumer in nature or part of a business or manufacturing process.

The Anatomy of an IoT System

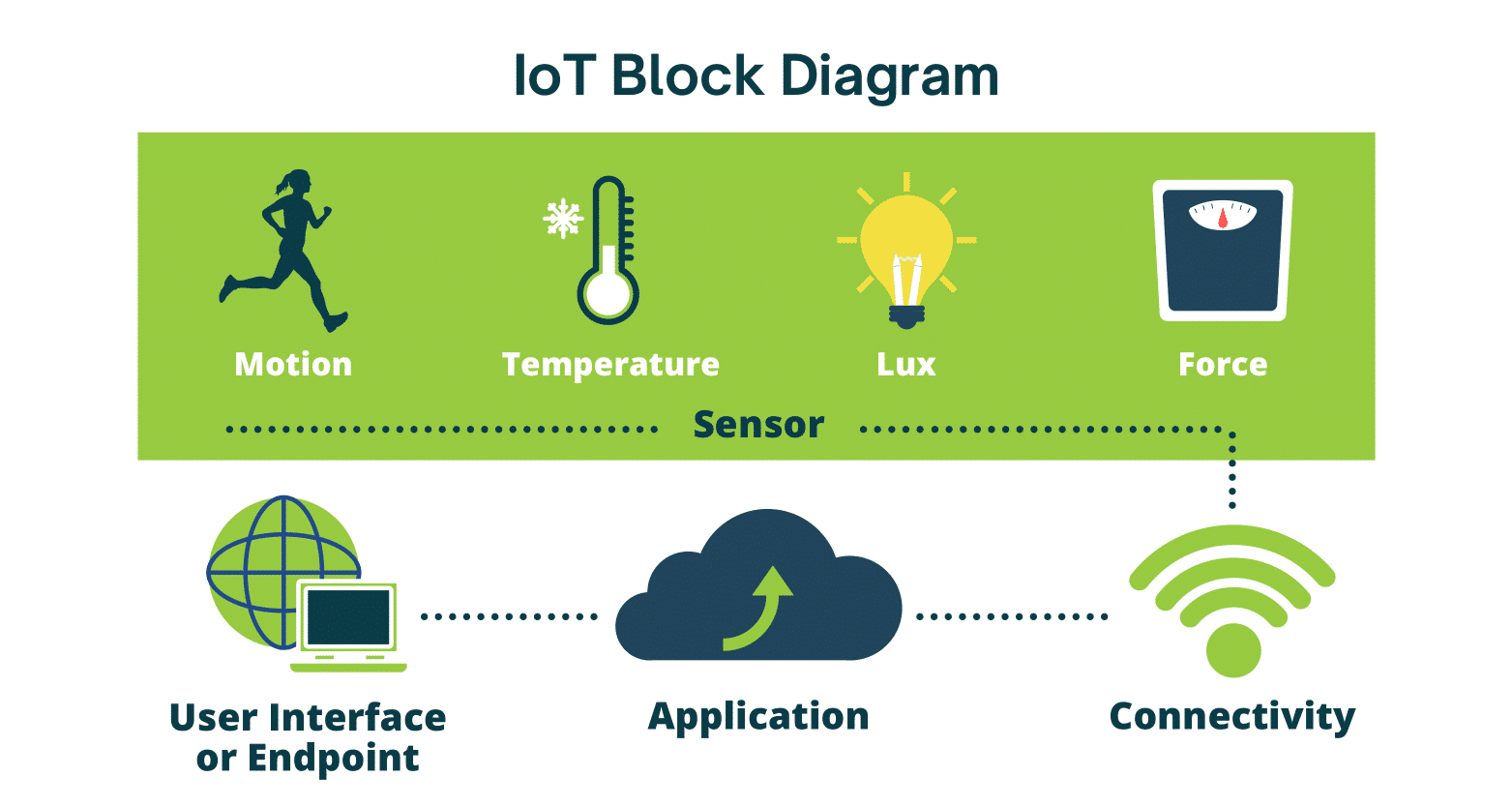

The goal of every IoT system is to collect environmental or system usage data to send it to an application. The application then makes intelligent decisions based on that data, then takes some action or provides some instruction to a device that ameliorates conditions at the point of data collection.

The following block diagram illustrates a typical IoT implementation:

Sensors

Sensors are the root of an IoT architecture. They generate the core of an IoT system’s value: data. This data can be anything measurable such as weight, temperature, pressure, moisture, or usage; the list of data categories can be quite long. Once generated, this data can be applied in many ways depending on the application that processes it.

Connectivity

This block in the diagram actually represents a wireless system rather than a single physical entity. This system could be a low power, local area network (LPLAN), standard wireless technology, WiFi, satellite or Bluetooth. Other technologies also exist but are less common. The choice depends on the needed tradeoff among these factors: range, bandwidth, and power consumption.

Application

IoT applications process collected data in order to determine a desired course of action. For example, they can determine if the data falls within a desired range (e.g., soil moisture in an agricultural setting). If it does not, the application messages a user interface or system; this system in turn takes corrective action (e.g., turn on an irrigation system).

User Interface/Endpoint

This block represents either a user interface or receiving system that processes instructions from the application. It is often co-located with or near the sensors.

Example of an IoT System: The Smart Kitchen

Let’s think back to the kitchen in the Carousel of Progress. We’ve been interacting with these features for several years now, with our Alexas and Nest Hubs. Let’s add a little IoT functionality by adding sensors to our appliances and connecting them to our home WiFi. Here we look at two appliances: the coffeemaker and the star of Disney’s show, the oven.

The Coffeemaker

For many of us, one of the most important appliances in our homes is our coffeemaker. For the coffee-addicts among us, this machine is vital for our brains to come alive each morning. And even more important are the coffee beans it extracts its magic from. The mere thought of running out of them motivates the java-dependent to take up valuable pantry space with an ample stash. The alternative is to make last-minute, sometimes inconvenient grocery store visits to ensure mornings run smoothly.

This necessity became the mother of the invention behind Bottomless, a Seattle-based company that was originally retail coffee distributor. When you would sign up for their service, Bottomless would send you not just the coffee, but a small scale. Instructions direct you to connect the scale to WiFi and then store your coffee container on its platform.

The connected device reports the declining weight to an application. This application then learns the average rate of diminishing supply, and predicts approximately when your coffee will run out. This date’s approach triggers an automatic shipment of the coffee the customer previously selected.

Interestingly, Bottomless has since changed its business model, realizing their core value was not just in coffee, but in automated ordering. The company has partnered with other companies to expand to other pantry staples.

In this way, IoT technology has improved the coffee connoisseur’s user experience in starting their day. Hoarding coffee is no longer an issue. The product arrives just in time without a trip to the grocery store; the shipment is triggered by actual consumption rather than by a schedule.

One can imagine that in the not so distant future, coffeemakers that store and grind beans will incorporate similar scales for even greater convenience. Add a WiFi-enabled feature of “ordering” your coffee from your bedside phone, and the coffee is freshly brewed and ready the moment you step into your kitchen.

The Oven

IoT has advanced the conventional oven in the Disney attraction beyond simple voice recognition. WiFi-connected smart ovens use a combination of sensors, instructions from apps and phone- or tablet-based user interfaces to create the perfect meal. For example, some use cameras to allow an app to identify the food placed in the unit. This, combined with a user-selected recipe, some weight, temperature and moisture sensors, allows the oven to tailor its temperature and cook time automatically to create that perfect roast.

In the past, many of these features existed mostly in countertop ovens. Since this article was originally published, smart built in wall ovens have joined the list of options. The breadth of options are featured in the Popular Science article, “The best smart ovens of 2023”.

IoT in Commercial Applications

Consumer IoT applications that have been around for a while and are ever expanding. Yet commercial and industrial applications are still evolving. Here we take a look at some possible Industrial IoT opportunities and motives for slower implementation.

Where IoT Can Improve Industrial Efficiency

In the same way that Bottomless’s scale manages personal coffee inventory, large industrial scales can add efficiency to the acquisition and storage of commercial raw materials. This just-in-time acquisition enabled by IoT sensors saves warehouse square-footage and increases efficiency.

This is just one of the industrial applications of wireless sensors in IoT. These devices are also extremely useful for real time structural monitoring, as described in the article Advantages and Applications of Wireless Load Cells. This real time structural monitoring can be critical where human safety is involved (see Improving the Safety of Scaffolding Using Sensors). Similarly, sensors within production processes can detect needed machine maintenance before catastrophic failures occur. This clearly saves downtime and potential lost productivity; in fact, a report by the US Department of Energy predicts a tenfold return on investment of predictive maintenance.

Achieving Multiple Business Goals With IoT

IoT implementations in manufacturing are most popular for operational intelligence, asset monitoring and maintenance. In fact, according to a 2019 PTC study, these are the top drivers for Industrial Internet of Things (IIoT) solutions for a full half of their respondents. Yet other drivers exist. The same report reveals a trend in IoT deployments to leverage data to resolve issues at all levels of business. “The common thread …[among] Industrial IoT beneficiaries is that the roles span across company levels and functions; an IIoT solution does not only benefit one employee.”

This ultimately has affected the rate of adoption of IoT solutions across all industries. Many IoT components have historically been provided by different vendors and designs were often in-house. However as IoT expertise grows, consultants are creating end-to-end IoT solutions through partnerships with these component vendors. This creates solutions tailored to the full suite of a business’ needs from operational efficiency to analysis of performance metrics. These solutions do so by parsing the data to applications spanning multiple business dimensions. When done properly these solutions can also leverage existing infrastructure and still offer scalability as IoT needs evolve.

Thus the rate of adoption of Industrial IoT is both a function of available technology and of identifying the scope.

Conclusions

Each scene in the Carousel of Progress shows us the latest innovations of that generation and how they improve the lives of its inhabitants. The IoT is just the next scene in our real-life version of that carousel.

The power of IoT lies in the two-way communication of endpoints and applications. With an effective data collection strategy, efficient mix of cloud and edge computing to process large amounts of data, and smart applications that add efficiencies to both businesses and consumer lives, the number of these improvements seems limitless.

Again, the data generation devices such as sensors and transducers are at the root of every IoT solution. This is where load cells come in. Wired to a wireless gateway, or wireless versions communicating with a wireless interface, Tacuna’s load cell offerings and wireless products can be the foundation for the right IoT deployment for your business application and project needs.

Further Reading

[1]

[2]

[3]

The State of Industrial Internet of Things 2019: Spotlight on Operational Effectiveness, Joe Biron, Shawn Kelley, David Immerman, Jon Lang, PTC Inc., 2019

IoT 101: An Introduction to the Internet of Things, Leverege LLC, 2018

IoTforAll.com/articles-overview

IoT Applications in Weighing and Loading, June 13, 2019