Our article, Measurement Uncertainty in Force Measurement, explains load cell measurement uncertainty calculations defined by standards bodies. These methods rely on very specific environmental conditions with very specific laboratory test equipment traceable to a primary standard.

However, in practice, this rigorous testing is expensive and usually reserved for highly sensitive instruments or applications that demand such precision. For most applications, proof that the load cell performs within specified tolerances is sufficient. To establish a clear set of these performance parameters, standards bodies have established load cell “classes” or levels of precision. Load cell product literature will then list the load cell’s class and the name of the standards body that defined that class. This indicates that the manufacturer has submitted a sample of that load cell model to a standards-approved laboratory for testing, and test results prove that the model complies with all the performance criteria for its listed load cell class.

When you buy a certified load cell, what does its load cell class specifically tell you about its measurement output? This document answers this question for NTEP-certified load cells.

Standards Bodies Governing Load Cells

NTEP (National Type Evaluation Program) is a non-profit organization that verifies whether a device meets the standards outlined in Handbook 44 by the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST). Below, we provide a summary of Handbook 44 [1], but you should refer to the full document for the most current information. We also summarize how NTEP certification is achieved.

For international standards, our companion article, Load Cell Classes: OIML Requirements, covers similar guidelines set by the International Organization of Legal Metrology (OIML) in Recommendation 60-1 (R60-1) [2].

Together, NIST and OIML define the standards for most load cells worldwide. While NIST standards apply within the United States, OIML compliance is essential for load cells sold internationally.

Background Concepts in Load Cell Requirements

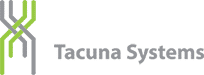

This section reviews basic terminology used in requirements for load cells and measuring systems. Figure 1 depicts them for further clarity.

Load Definitions

The common symbols used to describe loads, and their definitions, appear below.

Term

Symbol

Definition

Minimum Dead Load

\(E_{min}\)

The smallest load (expressed in mass units) that can be applied to a load cell.

Minimum Load of the Measuring Range

\(D_{min}\)

The smallest load (expressed in mass units) applied to the load cell under test, and is required to be within 10% of \(E_{min}\).

Maximum Capacity

\(E_{max}\)

The largest load (expressed in mass units) that can be applied to a load cell, per manufacturer’s specifications. It is usually well below the safe load limit.

Maximum Load of the Measuring Range

\(D_{max}\)

The largest load (expressed in mass units) applied to the load cell under test, and is required to be within 90% of \(E_{max}\)

Safe Load Limit

\(E_{lim}\)

The greatest load (expressed in mass units) that can be applied to the load cell without permanently changing the performance of the load cell.

Measuring Range Definitions

The common expressions for load cell measuring ranges are as follows.

Term

Symbol

Definition

Load Cell Measuring Range

\(D_{max} – D_{min}\)

The range of mass values used for testing

Maximum Measuring Range

\(E_{max} – E_{min}\)

The maximum range of mass values a load cell can accurately measure.

Verification Interval Definitions

The concept of a verification interval is important to the definition of load cell classes. The common related terms are as follows.

Term

Symbol

Definition

Load Cell Scale Divisions

\(d\)

The smallest unit quantity of weight the measuring device indicator can read; the resolution of the scale.

Load Cell Verification Interval

\(v\)

The quantity the load cell measuring range is divided into for testing.

Minimum Value of Verification Interval

\(e\)

The minimum quantity the scale’s measuring range is divided into for testing. This must be no more than 10 x \(d\) per NIST Handbook 44 requirements.

Maximum Number of Scale Divisions

\(n_{LC}\)

The maximum number of divisions that the maximum measuring range can be divided into. Note \(d\) x \(n_{LC}\) = the maximum measuring range.

Other Important Terms

Term

Apportioning Factor

Symbol

\(p_{LC}\)

Definition

A unit-less multiplier applied to a load cell observed error to quantify the portion of that error attributable to the load cell alone.

NIST Load Cell Classes and Their Required Performance

With the common understanding of these key terms, we can define each NIST load cell class and describe the measurement tolerances and precision associated with each.

NIST Classes and Their Commercial Application

NIST assigns five classes to load cells: I, II, III, III L, and IIII based on their applications. (See Table 7a in the Handbook.)

NIST Load Cell Class

Application

I

Precision Laboratory Weighing

II

Laboratory weighing, precious metals and gems, grain test scales

III

All commercial weighing including grain test scales, retail precious metals and semi-precious gem weighing, grain-hopper scales, animal scales, postal scales, laundry scales and on-board vehicle weighing systems up to a 30,000lb capacity

III L

Large capacity commercial scales such as vehicle scales, on-board vehicle weighing systems with a capacity greater than 30,000 lbs, axle load scales, livestock, railway track, crane and hopper scales (other than grain hoppers)

IIII

Weight measurement for highway weight enforcement such as axle load weighers

Scale Divisions (Minimum Resolution) and Full Scale Requirements Per NIST Load Cell Class

For each of these load cell classes, NIST specifies:

- the number of divisions \(n\)),

- the value of the load cell scale divisions (\(d\)), and

- the minimum value of the verification scale (\(e\)).

The table below summarizes these generically, based on Table 3 from [1]. NIST has additional, application-specific verification scale minimums that are listed in Handbook 44.

Table 1: Parameters for Accuracy Classes

| Class |

Value of Verification Scale Division (d or e) |

Number of Scale Divisions (n) | |

| Minimum | Maximum | ||

| SI Units | |||

| I |

equal to or geater than 1 mg |

50,000 | — |

|

II |

1 to 50 mg, inclusive |

100 | 100,000 |

| equal to or greater than 100 mg | 5,000 | 100,000 | |

| III |

0.1 to 2 g, inclusive |

100 | 10,000 |

|

equal to or greater than 5 g |

500 | 10,000 | |

| III L | equal to or greater than 2 kg | 2,000 | 10,000 |

| IIII | equal to or greater than 5 g |

100 | 1,200 |

| U.S. Customary Units | |||

| III | 0.0002 lb to 0.005 lb, exclusive | 100 | 10,000 |

| 0.005 oz to 0.125 oz, inclusive | 100 | 10,000 | |

| equal to or greater than 0.01 lb | 500 | 10,000 | |

| equal to or greater than 0.25 oz | 500 | 10,000 | |

| III L | equal to or greater than 5 lb | 2,000 | 10,000 |

| IIII | greater than 0.01 lb | 100 | 1,200 |

| greater than 0.25 oz | 100 | 1,200 | |

Maximum Permissible Error Per Load Cell Class

Unlike OIML, NIST specifies the MPE primarily to quantify permissible errors due to creep and creep recovery. The table below (from Table T.N.4.6 of [1]) gives the MPE per load cell class for type evaluation testing only. (Type evaluation testing is the NIST term for testing performed for certification, as opposed to maintenance testing. Note that for legal-for-trade applications, a scale owner must periodically demonstrate standards compliance through maintenance calibrations and testing.)

Table 2: MPE During Type Evaluation For Each Load Cell Class

| MPE in Load Cell Verifications Divisions (v) = pLC × Basic Tolerance in v | |||

| Class | pLC × 0.5 v | pLC × 1.0 v | pLC × 1.5 v |

| I | 0 – 50,000 v | 50,001 v – 200,000 v | 200,001 v + |

| II | 0 – 5,000 v | 5,001 v – 20,000 v | 20,001 v + |

| III | 0 – 500 v | 501 v – 2,000 v | 2,001 v + |

| IIII | 0 – 50 v | 51 v – 200 v | 201 v + |

| III L | 0 – 500 v | 501 v – 1,000 v |

Add 0.5 v to the basic |

Where \(v\) represents the load cell verification interval (which is similar to \(e\)), and, again, \(p_{LC}\) is the apportionment factor. NIST gives specific apportionment factor values per application as follows:

\(p_{LC}\) = 0.7 for load cells of any class other than III L marked “S” for single load cell application use

\(p_{LC}\) = 1 for load cells of any class other than III L marked “M” as intended for multiple load cell applications

\(p_{LC}\) = 0.5 for Class III L load cells marked either M or S

Tolerance Types and Values per Class

In addition to MPE, NIST specifies tolerances per load cell class, as a function of the load cell scale divisions. For type evaluation testing, the tolerance values account for hysteresis within a specified temperature range, barometric pressure and power supply. For all other testing, the load cell must fall within the tolerances regardless of ambient conditions. However, these tolerances are generally twice the limit of those used for type evaluation testing.

Specifically, NIST defines two types of tolerances:

- Acceptance tolerances and

- Maintenance tolerances

Acceptance Tolerances

Acceptance tolerances (again, half the maintenance tolerances) apply:

- when performing load cell type evaluation,

- before deploying a weighing device for commercial use for the first time,

- within 30 days of corrective service for any NTEP non-compliance, or

- within 30 days of an overhaul or reconditioning of the system.

Maintenance Tolerances

Maintenance tolerances apply to equipment in use, or field testing tolerances.

The general tolerance requirements per load class are given in the table below for maintenance testing (from Table 6 of [1]). NIST, however, has additional requirements for specific applications (such as postal scales, multiple vs single load cell applications). For this reason, the weighing device owner should consult Handbook 44 for specifics.

The table tells us that if we have, for example, a Class III load cell with a test load equal to 6000 x \(d\) (again \(d\) being the load cell’s scale division value), the load cell must read within 2 scale division values of 6000 x \(d\) (meaning it must read within 5998\(d\) and 6002\(d\)).

Table 3: Maintenance Tolerances Per Accuracy Class

| Tolerance in Scale Divisions | ||||

| 1 | 2 | 3 | 4 | |

| Class | Test Load | |||

| I | 0 – 50,000 | 50,001 – 200,000 | 200,001 + | — |

| II | 0 – 5,000 | 5,001 – 20,000 | 20,001 + | — |

| III | 0 – 500 | 501 – 2,000 | 2,001 – 4,000 | 4,001 + |

| IIII | 0 – 50 | 51 – 200 | 201 – 400 | 401 + |

| III L | 0 – 500 | 501 – 1,000 | Add 1 d for each additional 500 d or fraction thereof |

|

Limits on Repeatability Error

NIST only requires that repeated weighings of the same load must agree within the maintenance tolerances given in Table 3. The requirements do not specify how many weighings within a certain time need to fall within these limits.

Limits on Creep Error

NIST requirements for creep error limits are similar to OIML’s but slightly more permissive. Like OIML, NIST assumes a maximum recommended load (\(D_{max}\)) that is within 90-100% of the maximum capacity (\(E_{max}\)). Handbook 44 requires that a compliant load cell, when loaded with its maximum recommended load (\(D_{max}\)) for 30 minutes, has a final reading that differs from its initial reading by no more than the absolute value, |MPE| calculated from Table 2.

The NIST requirement for 20-30 minutes of \(D_{max}\) is identical to OIML. That is, a compliant load cell, when loaded with its maximum recommended load (\(D_{max}\)) for 30 minutes, must have a final reading that differs from its reading after 20 minutes by no more than 0.15 x |MPE|.

Limits on Dead Load Output Return Per Load Cell Class

Recall this requirement describes the performance of the load cell when measuring a load equal to the minimum weight (\(D_{min}\)) immediately before and immediately after the above 30-minute creep test.

NIST requires that after a 30-minute creep test, the reading of minimum load \(D_{min}\) must not differ from the pre-test reading by more than:

Class

Recovery Value

II and IIII

\(0.5v\)

III with \(n \leq 4000\)

\(0.5v\)

III with \(n > 4000\)

\(0.83v\)

III L

\(2.5v\)

Ambient Conditions Where Limits Must Be Met

Temperature

Like OIML, NIST performance tolerances and MPE apply within a default temperature range of \(-10^{\circ}\)C through \(+40^{\circ}\)C , or \(14^{\circ}\)F through \(104^{\circ}\)F, for all classes.

If the measurement system is designed to operate within a different temperature range, NIST requires that this range must span at least the following, depending on class:

Accuracy Class

Class I

Class II

Class III, III L, IIII

Minimum Temperature Span

\(5^{\circ}\)C (\(9^{\circ}\)F)

\(15^{\circ}\)C (\(27^{\circ}\)F)

\(30^{\circ}\)C (\(54^{\circ}\)F)

For Class III and greater, NIST requires that the measuring device display no reading when the measuring device’s ambient temperature is outside the specified temperature range. Readings should only resume when the device itself achieves a temperature within its specified range.

Temperature effect on zero balance

The zero value for a compliant load cell cannot vary by more than 3 divisions per \(5^{\circ}\)C or \(9^{\circ}\)F for a Class III L load cell; it cannot vary by more than 1 division per \(5^{\circ}\)C or \(9^{\circ}\)F for all other load cell classes.

Barometric Pressure

For all load cell classes except for Class I, the zero indication variance must be one scale division or less for a change in barometric pressure of 1 kPa over the total barometric pressure range of 95 kPa to 105 kPa (28 in to 31 in of Hg).

Other Environmental Factors

NIST further specifies tolerances and cut off values (beyond which the system should not give a reading) for radio disturbances, power interruptions and low power. These are found in Handbook 44 Section 2.

NTEP Certificates of Compliance

Again, the National Type Evaluation Program (NTEP) is responsible for testing measuring equipment and issuing certificates of compliance. A device receives an NTEP certificate when it passes rigorous (sometimes months long) testing against the above requirements at an NTEP-approved laboratory. Typically, a manufacturer seeking to use their product for trade, commerce, law enforcement, or government data collection submits a sample unit to the laboratory. If the equipment fails, it must be resubmitted within 90 days. If a design fails three testing cycles, it will be rejected unless the manufacturer provides acceptable proof that it has corrected the model’s deficiencies.

Compliance Test Equipment Accuracy

NIST specifies the error of the test equipment used to certify measuring systems as equal to or less than either:

- 1/3 the allowed load cell tolerance, or

- 70% of the tolerance of the entire end-to-end measuring system.

Required Labeling for Compliant Devices

To obtain a certificate of compliance, a weighing device must not only pass performance tests; it must also display at least the following markings:

- Manufacturer’s identification

- Model number

- Serial number

- Load cell accuracy class

- Nominal capacity and value of the scale division (\(d\))

- Any special operating temperature range, if outside the \(14^{\circ} – 104^{\circ}\)F default

- Whether rated for single or multiple load cell applications

Active vs Inactive NTEP Compliance

A load cell with active status of NTEP conformance is a device manufactured, sold or deployed having a current certificate of conformance. This means the tested prototype of that load cell has has attained NTEP compliance, and the certification continues to be maintained. A load cell sold with inactive NTEP conformance status is a device that was manufactured under an active certificate of conformance, but the certificate has since expired while the device has been in inventory or in commercial use.

Whole System vs. Component Compliance

Often, laboratories test only components of a measuring system (for example, individual load cell models) rather than the entire system. A system built with certified components is not itself considered compliant unless it as a whole is also tested for compliance. Conversely, if a whole measuring device is certified as compliant, the individual load cell(s) in the system is/are not considered individually certified unless they have been individually tested. Therefore, if its internal load cells are replaced with a different model, a measuring system will no longer be NTEP compliant without passing compliance tests anew.

The component manufacturer is responsible for compliance testing of its component models; likewise the scale manufacturer is responsible for obtaining its system’s certificate of compliance. See our article on legal for trade scales for more information on whole system compliance.

Conclusion

This document has explained at a high level the tolerances and performance requirements imposed by NIST. A certified load cell of a specified class should meet these requirements with 100% certainty with regular calibration. When they do not meet these tolerances, the certified load cell must be taken out of service to be repaired or replaced.

This document also explains how load cell class relates to its divisions of resolution. These divisions help determine the measurement intervals detectable by a weighing system using that particular load cell. For more detailed information on this topic, see our article What Is the Lowest Weight a Load Cell Can Measure.

As always, contact Tacuna Systems with any issues regarding our load cells behaving outside of their specifications.

References

[1]

NIST Handbook 44, Specifications, Tolerances, and Other Technical Requirements for Weighing and Measuring Devices, as adopted by the 104th National Conference on Weights and Measures, 2019, National Institute of Standards and Technology, US Department of Commerce (latest version, 2025 as adopted by the 109th National Conference on Weights and Measures)

[2]

OIML R 60-1, Metrological regulation for load cells Part 1: Metrological and technical requirements, Organisation Internationale de Métrologie Légale, Edition 2017 (latest version 22 November 2021)

[3]

R 60 OIML-CS rev.2 Additional requirements from the United States Accuracy class III L, Organisation Internationale de Métrologie Légale, January 2018