If you buy a certified load cell, then what does its load cell class tell you? This guide explains the answer for OIML-certified load cells, including their required performance tolerances and how they relate to your application. More details can be found in the original, published OIML requirements.

For U.S.-specific guidance, see our companion article: Load Cell Classes: NIST Requirements.

Why Load Cell Classes Exist

In Measurement Uncertainty in Force Measurement, we discussed the standards-body-approved procedures for mathematically calculating the total uncertainty for a given load cell. These procedures are based on very specific environmental conditions with very specific laboratory test equipment traceable to a primary standard. While this highly precise lab testing of every load cell is ideal, it’s costly and impractical for large-scale manufacturing. Standards bodies like OIML address this by creating load cell classes—categories with specific performance benchmarks.

What proof do we have that a load cell meets these tolerances? Certification testing and approval provide that assurance. For a measuring device (load cell or scale) to earn certification, its manufacturer must submit each new design to an approved laboratory for testing. The device is certified when it meets all the performance requirements for its class.

Standards Bodies Governing Load Cells

This document will cover requirements published by the International Organization of Legal Metrology (known as OIML from the organization’s name in French) in its Recommendation 60-1 (abbreviated R60-1). Its companion document, Load Cell Classes: NIST Requirements, will cover similar requirements by the US Department of Commerce’s National Institute of Standards and Technology (NIST) Handbook 44. Together, NIST and OIML define the standards for most load cells sold globally.

Background Concepts

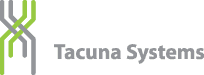

This section reviews basic terminology used in requirements for load cells and measuring systems. Figure 1 depicts them for further clarity.

Load Definitions

The common symbols used to describe loads, and their definitions, appear below.

Term

Symbol

Definition

Minimum Dead Load

\(E_{min}\)

The smallest load (expressed in mass units) that can be applied to a load cell.

Minimum Load of the Measuring Range

\(D_{min}\)

The smallest load (expressed in mass units) applied to the load cell under test, and is required to be within 10% of \(E_{min}\) .

Maximum Capacity

\(E_{max}\)

The largest load (expressed in mass units) that can be applied to a load cell, per manufacturer’s specifications. It is usually well below the safe load limit.

Maximum Load of the Measuring Range

\(D_{max}\)

The largest load (expressed in mass units) applied to the load cell under test, and is required to be within 90% of \(E_{max}\)

Safe Load Limit

\(E_{lim}\)

The greatest load (expressed in mass units) that can be applied to the load cell without permanently changing the performance of the load cell.

Measuring Range Definitions

The common expressions for load cell measuring ranges are given below.

Term

Symbol

Definition

Load Cell Measuring Range

\(D_{max} – D_{min}\)

The range of mass values used for testing

Maximum Measuring Range

\(E_{max} – E_{min}\)

The maximum range of mass values a load cell can accurately measure.

Verification Interval Definitions

The concept of a verification interval is important to the definition of load cell classes. The common related terms are as follows.

Term

Symbol

Definition

Load Cell Verification Interval

\(v\)

The quantity (expressed in units of mass) the load cell measuring range is divided into for testing.

Minimum Load Cell Verification Interval

\(v_{min}\)

The smallest quantity (expressed in mass units) that the maximum measuring range can be divided into.

Maximum Number of Load Cell Intervals

\(n_{LC}\)

The maximum number of divisions that the maximum measuring range can be divided into. Note \(v_{min}\) x \(n_{LC}\) = the maximum measuring range. This quantity is determined by the smallest division of mass the load cell can read. For example, if a load cell with a maximum measuring range of 3000kg is capable of reading in 1kg increments, \(n_{LC}\) = 3000.

Other Important Terms

Term

Apportioning Factor

Symbol

\(p_{LC}\)

Definition

A unit-less multiplier applied to a load cell observed error to quantify the portion of that error attributable to the load cell alone.

A Word About Requirements Scope

The specifications summarized below apply to a measuring device from the platform to the load cell output (analog) or ADC output (when analog output is converted to digital). They do not include allowable errors introduced by downstream signal conditioners or readout/storage devices. These additional cases are discussed in Section 5.7 of [1] and in OIML R76, Nonautomatic Weighing Instruments. The latter discusses requirements for whole measuring systems, whereas R60 is specific to load cell output in raw form.

OIML R60-1 Load Cell Class Definitions

OIML categorizes load cells into the following four accuracy classes depending on the granularity of measurements in their maximum measuring range. They are: Class A, Class B, Class C and Class D. Class A load cells are the most granular or accurate, having the highest number of load cell verification intervals in their maximum measuring range, whereas Class D load cells have the least intervals in their measuring range. The table below (Table 1 in [1]) gives the range of load cell verification intervals per load cell class.

Table 1: Maximum Number of Load Cell Verification Intervals, \(n_{LC}\) , by Accuracy Class

| Class A | Class B | Class C | Class D | |

| Lower Limit | 50,000 | 5,000 | 500 | 100 |

| Upper Limit | Unlimited | 100,000 | 10,000 | 1,000 |

Maximum Permissible Error Per Load Cell Class

The maximum permissible error (MPE) of each load cell accuracy class is calculated per the table below.

Table 2: Maximum MPE On Type Evaluation by Accuracy Class (Table 4 in [1])

| MPE

(+/-) | Load, m | |||

| Class A | Class B | Class C | Class D | |

| pLC × 0.5 v

pLC × 1.0 v

pLC × 1.5 v

| 0 ≤ m ≤ 50,000 v

50,000 v < m ≤ 200,000 v

200,000 v < m | 0 ≤ m ≤ 5,000 v

5,000 v < m ≤ 20,000 v

20,000 v < m ≤ 100,000 v | 0 ≤ m ≤ 500 v

500 v < m ≤ 2,000 v

2,000 v < m ≤ 10,000 v | 0 ≤ m ≤ 50 v

50 v < m ≤ 200 v

200 v < m ≤ 1,000 v |

This error limit applies to errors due to non-linearity, hysteresis, and temperature effect on sensitivity within the range \(-10^{\circ}\) to \(+40^{\circ}\) C, unless special limits apply per Section 5.6 of [1].

An example of how to calculate the MPE using Table 2 above is as follows, assuming the default apportioning factor of 0.7:

- Assumption: Class C load cell with a maximum measuring range of 3000 kg and 3000 verification intervals (each measurement interval, \(v\), is 1 kg).

- Result: the MPE = 0.7 x 0.5 x 1 kg, which equals 0.35 kg (when the applied load is between 0 and 500 kg, since 500\(v\) = 500 kg, from the table).

This means the combined error for the Class C3 load cell, when measuring weights under and including 500 kg, can be no more than 0.35 kg. Similar calculations from the table tell us:

- MPE = 0.7 kg when the load cell measures from over 500 kg up to and including 2000 kg.

- MPE = 0.7 x 1.5 x 1 kg = 1.05 kg when the load cell bears a mass from over 2000 kg to 3000 kg.

Limits on Repeatability Error Per Load Cell Class

OIML requires that the results of repeated weighings differ by no more than the following:

- For a Class A or B load cell: the absolute value of MPE for that load, \(m\), in Table 2 above after 5 identical load applications.

- For Class C and D load cells: the absolute value of MPE for three identical load applications.

Limits on Creep Error

The requirements for creep performance in Section 5.5.1 of [1] are identical for all load cell classes, A, B, C or D. They assume a maximum recommended load (\(D_{max}\)) that is within 90-100% of the maximum capacity (\(E_{max}\)).

OIML requires that a compliant load cell, when loaded with its maximum recommended load (\(D_{max}\)) for 30 minutes, has a final reading that differs from its initial reading by no more than 0.7 x |MPE| calculated from Table 2 above. The standard requires the MPE calculation for creep to use 0.7 as the apportioning factor regardless of the actual one given by the manufacturer.

Moreover, OIML requires that a compliant load cell, when loaded with its maximum recommended load (\(D_{max}\)) for 30 minutes, has a final reading that differs from its reading after 20 minutes by no more than 0.15 x |MPE|.

Using our previous load cell as an example, a C3 load cell of \(E_{max}\) = 3000 kg, (meaning \(v\) = 1 kg) and assuming \(D_{max}\) = \(E_{max}\) and \(p_{LC}\) = 0.7:

the |MPE| = 0.7 x 1.5 x 1 kg = 1.05 kg, and

the reading at 30 minutes cannot differ from the initial reading by more than:

0.7 x 1.05 kg = 0.735 kg.

Likewise the reading at 30 minutes cannot differ from the reading at 20 minutes by more than:

0.15 x 1.05 kg = 0.1575 kg.

Limits on Dead Load Output Return (DR)

This requirement describes the performance of the load cell when measuring a load equal to the minimum weight (\(D_{min}\)) immediately before and immediately after the above 30-minute creep test. OIML requires that the reading of load, \(D_{min}\), prior to the creep test not differ from the reading immediately after the test by more than half of the load verification interval, \(v\). That is, DR \(\leq\) 0.5 \(v\), or in our example, where \(v\) = 1 kg, the deal load output return cannot exceed half a kilogram.

Ambient Conditions Applicable TO OIML Requirements

OIML requirements stipulate the ambient conditions, including temperature, humidity, and barometric pressure, within which the above error limits apply. Therefore, in order to achieve the expected load cell results from an OIML certified load cell, the application must adhere to these stated limits. Alternatively, additional testing under conditions beyond those specified in this section can supplement but not replace the testing within these limits.

Temperature (By Load Cell Class)

The default temperature range for any class of OIML certified load cell is \(-10^{\circ}\)C to \(+40^{\circ}\)C. However, OIML is very clear that this can be overridden by national standards pertaining to the physical location where the load cell operates. Where these special limits apply, OIML specifies the minimum required span of temperatures by class.

Accuracy Class

Class A

Class B

Class C, D

Minimum Temperature Span

\(5^{\circ}\)

\(15^{\circ}\)

\(30^{\circ}\)

OIML also gives a requirement for temperature response for the dead load output. Within the standard or special operating temperature ranges of the load cell, the minimum weight of the measuring range, \(D_{min}\), cannot vary by more than the apportioning factor times the minimum verification interval:

(\(p_{LC}\) x \(v\))

for every \(2^{\circ}\)C for a Class A cell, or \(5^{\circ}\)C for the remaining classes. So for our example load cell, if a dead load measurement is taken at \(0^{\circ}\) and at \(10^{\circ}\)C, the measurement at \(10^{\circ}\)C can’t be more than

0.7 x 1 kg x 2, or 1.4 kg

different than the one at \(0^{\circ}\)C.

Barometric Pressure

An OIML compliant load cell cannot vary in its output by more than the minimum verification interval, \(v_{min}\), for every change of 1 kPa in barometric pressure.

Humidity

OIML requires a humidity rating for every load cell, and this rating must be included in the labeling of the load cell if it is not the default. OIML humidity ratings fall into one of three categories:

Humidity Rating

CH

NH

SH

Acceptable Ambient Condition for the Load Cell

Cyclic Humidity (considered the default)

No Humidity

Steady State Humidity

For default humidity rated (CH or unmarked) load cells, the influence of temperature cycles specified in the OIML requirements R60-2, Part 2: Metrological controls and performance tests, can’t be more than the verification interval, \(v\), on the maximum allowed load, \(D_{max}\).

For SH rated load cells, exposure to humidity in the test ranges specified in OIML R60-2 cannot affect the MPE calculated from Table 2 in this post at all, to be deemed compliant.

OIML-Required Labeling

As a final word about OIML requirements, this section gives the required load cell labeling. OIML requires certified load cells to be labeled with, or have in their literature (depending on load cell size so that markings may be legible):

\(\bullet\)

Load cell accuracy class:

A, B, C or D

\(\bullet\)

Number of load cell divisions:

Given in thousands, after the accuracy class. Our example load cell above would be marked “C3” since it has 3000 divisions.

\(\bullet\)

The intended load application:

Compression, tension, beam or universal, indicated with arrows

\(\bullet\)

Temperature rating:

Given if the default range does not apply (\(-10^{\circ}\) to \(40^{\circ}\) )

\(\bullet\)

Humidity rating:

SH or NH (CH is optional since it is the default)

Conclusion

This document has explained at a high level the tolerance requirements for each OIML-defined load cell class. In an ideal world, a tested load cell of a specified class will meet these tolerances with 100% certainty with regular calibration. (Note that the specifications given in the load cell data sheet express the characteristics of that particular load cell when properly calibrated, and fall within any required tolerances for certification.) The higher the load cell quality, the more this should be true. When a load cell does not meet these tolerances, it must be taken out of service to be repaired or replaced.

This document also covers how load cell class relates to its number of divisions. These divisions and the maximum measuring range determine the measurement intervals detectable by the load cell. For more detailed information on this topic, see our article What Is the Lowest Weight a Load Cell Can Measure.

As always, contact Tacuna Systems with any issues regarding our load cells behaving outside of their specifications.

References

[1]

OIML R 60-1, Metrological regulation for load cells Part 1: Metrological and technical requirements, Organisation Internationale de Métrologie Légale, Edition 2017 (latest version 22 November 2021)

[2]

R 60 OIML-CS rev.2 Additional requirements from the United States Accuracy class III L, Organisation Internationale de Métrologie Légale, January 2018 (latest version 22 November 2021)

[3]

NIST Handbook 44, Specifications, Tolerances, and Other Technical Requirements for Weighing and Measuring Devices, as adopted by the 104th National Conference on Weights and Measures, 2019, National Institute of Standards and Technology, US Department of Commerce (latest version, 2023 as adopted by the 107th National Conference on Weights and Measures)