Load Cells

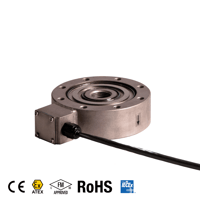

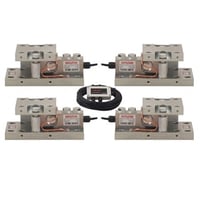

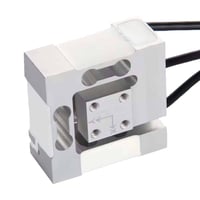

We carry a broad selection of commercial-grade strain gauge load cells and force sensors by Tacuna Systems, ANYLOAD, and AmCells. These certified standards-compliant brands offer the highest level of quality and reliability, even in the most demanding environments.

To help ensure your project’s success, we offer expert design support with every purchase, upon request.

Not sure which sensor you need? Visit our knowledge base for side-by-side comparisons, including their differentiating features, ideal applications, and guidance on choosing the right load cell material.

Ordering through our secure online store is fast and simple. Contact us with any questions.