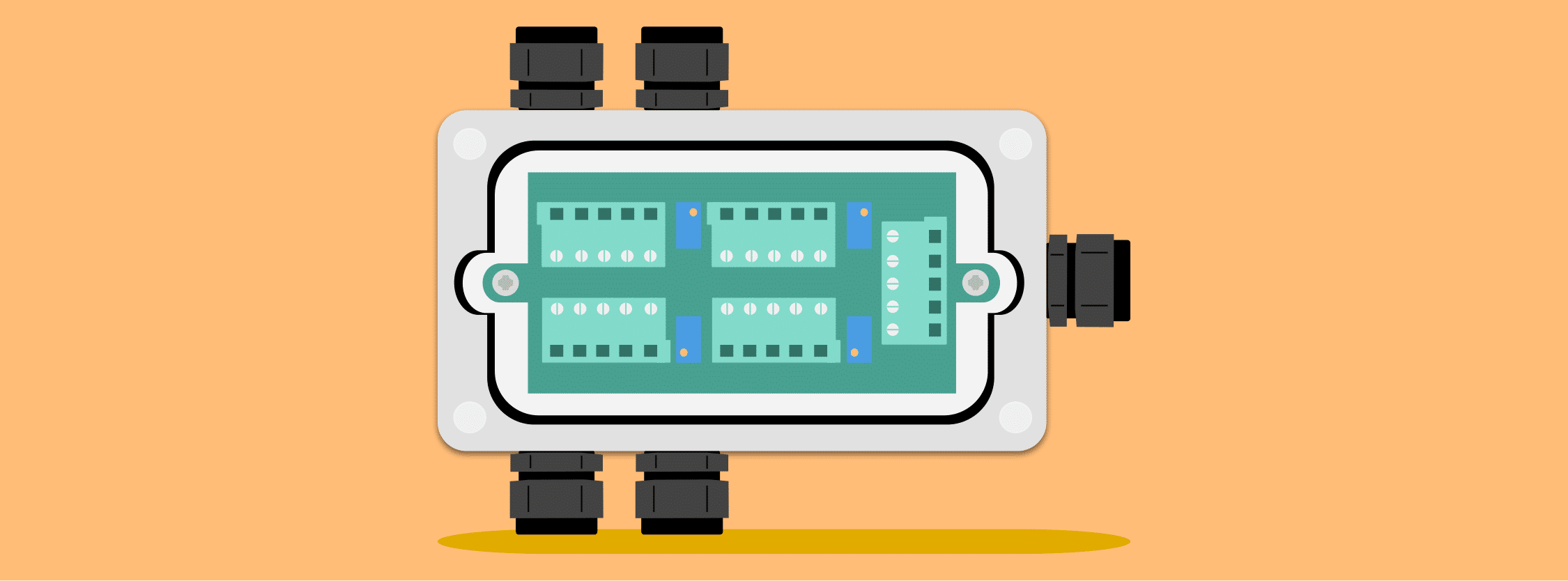

Large-scale and complex weighing systems often require multiple load cells to record accurate measurements. These multiple load cell devices are arranged symmetrically around the corners of the measurement platform. This distributes the weight over a wider physical area. In this case, a junction box or summing box combines the measurement signals from these distributed load cells. The result is a useful, combined or “summed” digital output. These junction boxes are built to withstand tough environments and are easily installed with most measurement applications. (For a real example of junction box use in force measurement, see Research With Load Cells: Effects of Military Load Carriage on Ground Reaction Forces or Giving a crap: How a Simple Toilet and Load Cells are Tackling Global Ills in our “Featured Customer Projects” section of our Knowledge Base.)

How does one guarantee measurement accuracy then, regardless of where the weight is placed on such a loading platform? Trimming is a process of equalizing the inputs from these multiple load cells into a single, accurate, output. As this article will explain further, summing or junction boxes trim the inputs from each load cell through potentiometers connected to each individual load cell.

When Does Load Cell Trimming Need To Be Done?

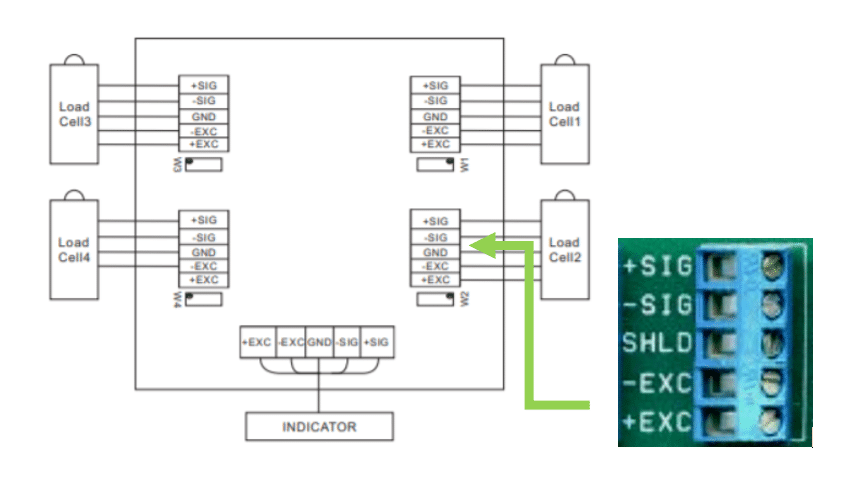

In multi-cell applications, load cells or sensors are physically wired to the junction box in parallel, which instantaneously sums the data. The trimming process is necessary in these multi-cell systems before they can generate quality data for operators. Load Cell trimming is widely used in tank measurements, industrial truck scales, and hopper and bin weighing apparatuses.

In any of the following scenarios, all input signals to the junction box must be adjusted or “trimmed” to form a cohesive measurement system.

- Asymmetrical Loading. Load cell trimming guarantees that measurements are correct, regardless of the placement of the object or objects on the scale. When a platform supports the load, each load cell or “corner” will not share an equal distribution of the weight. This is especially true for objects that have a variable center of gravity. Examples include poured gravel, or a pile of packages dropped on a scale.

- Unequal Load Cells. If the geometry of the measuring system is asymmetrical or prevents the use of identical load cells at the corners, the load cells must be trimmed. This must take place before calibrating the measurement system.

- “Legal-For-Trade” Applications. Scales used for the sale of goods or products commercially by weight must be “legal-for-trade” or “trade-approved” scales. The trimming of load cell signals reduces inaccuracies that could cause improper charging of customers. Examples of “legal-for-trade” applications are airport luggage, grocery, and truck scales.

Types of Load Cell Trimming

There are two main types of load cell trimming: excitation trimming and signal trimming.

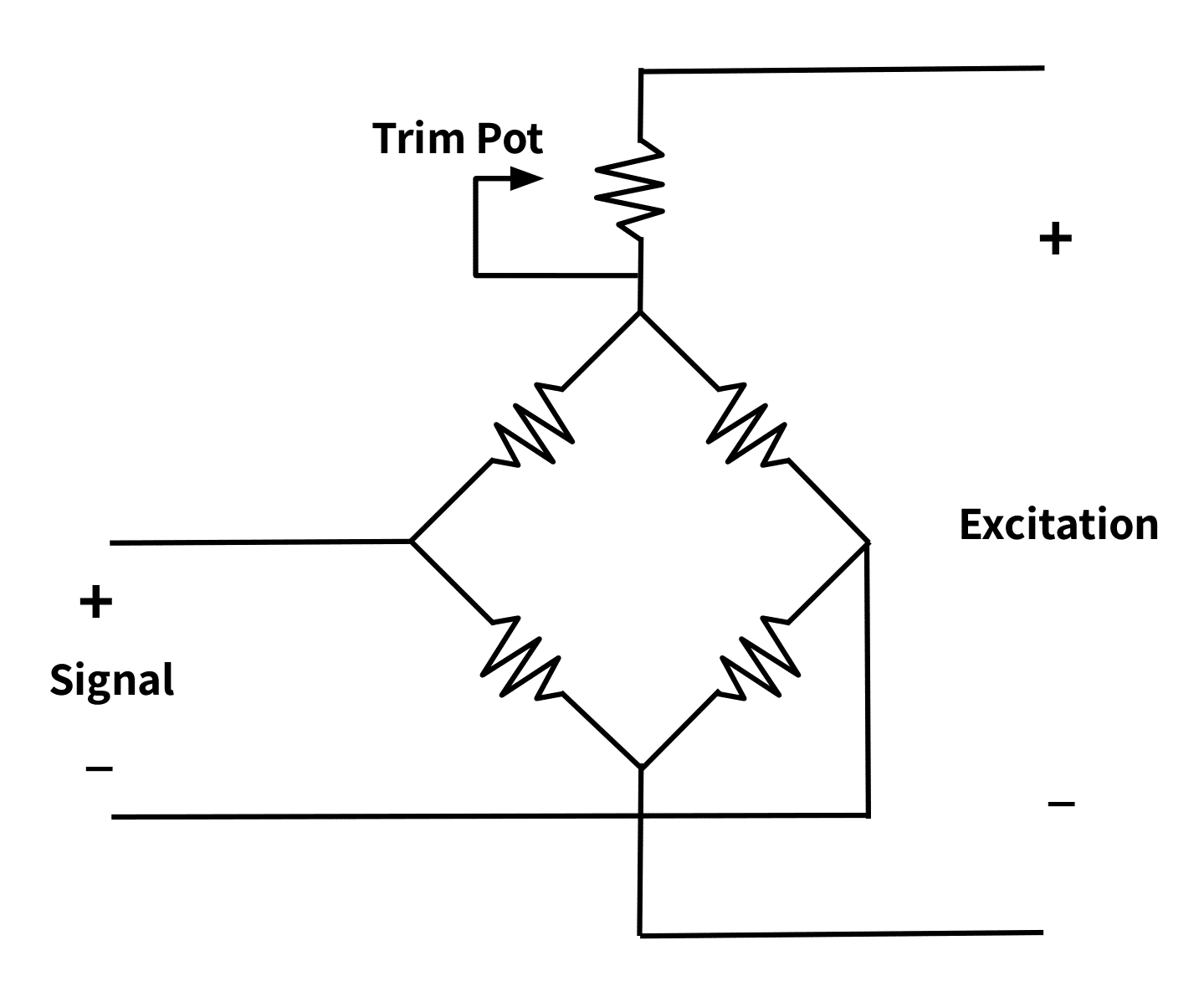

Excitation Trimming

The strain gauges that make up the load cell transducer require an excitation voltage or current. Excitation trimming adds a series resistor to reduce the excitation voltage passed through the load cell. This resistance changes through the use of a trimmer potentiometer, or trim pot, per the diagram below.

The trimming process (described in detail later) involves setting a known fixed weight on each load cell and adjusting its output individually until the indicated readings for all of them are equal. When the trim pot resistance is adjusted, the excitation supply increases or decreases, tuning the indicated weight.

When trimming is complete and the whole system is operating, the individual load cell with the lowest signal output receives the full excitation. The remaining load cells receive proportionally smaller excitation. This ensures the total load measurement is equivalent for all load cells in the system.

Excitation trimming is not just for tuning load cells, but also for compensating for variance in the measurement output.

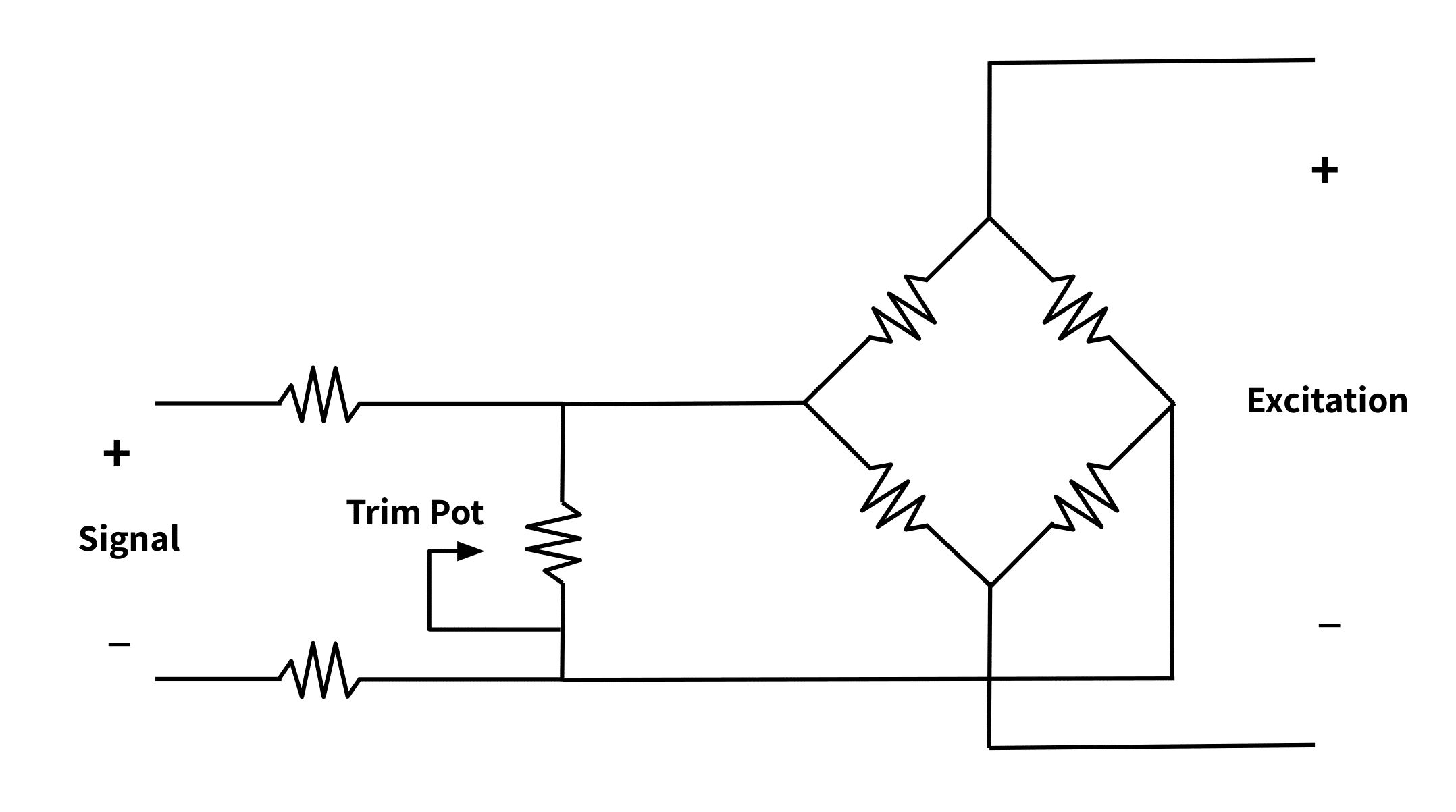

Signal Trimming

Signal trimming is sometimes preferable because it proves easier to troubleshoot errors and faults. Also, it is less susceptible to temperature changes or vibrations. This form of trimming is compatible with most load cell indicators (displays), and works with limited or gated power supplies.

With this method, isolation resistors are placed in parallel between the +/- terminals of each load cell. These parallel resistors create a path for the load cell signal to “leak” before it reaches the junction. A trim pot is connected to allow adjustment of individual load cell signals, as seen in the figure below.

The resistors do not fully isolate the individual load cells from each other; however they provide enough separation to prevent individual load cell measurements from interfering with each other.

This approach allows for the adjusting of each load cell’s reading to a standard value. This guarantees that the corner adjustment can remain the same even if you replace the load cell.

The Load Cell Trimming Procedure

While selecting the appropriate load cells and installing them correctly is important to a multi-cell measurement system, trimming is equally important. Improperly trimmed load cells give unreliable measurements, rendering them useless. Properly setting up and installing the junction box is critical to the summing and trimming process.

For best results always follow the manufacturer’s installation instructions. Ensure that installers are properly trained prior to installation. However, if questions or concerns arise while installing our products, contact Tacuna Systems immediately.

Individual Load Cell Trimming

Before trimming, make sure operators have proper training and wear appropriate protective equipment. Installation only requires a flat-head screwdriver for potentiometer adjustment, a Philips-head screwdriver for fastening bolts, and a multi-meter. For best results, follow the steps below.

The Steps:

- Each individual potentiometer is factory-set to 5 Ω with a maximum capacity of 10 Ω. Use the multi-meter to verify that each potentiometer’s resistance is 5 Ω. If the resistance varies, turn the adjustment knob counterclockwise to increase, and clockwise to decrease.

- Connect each load cell-device cable and the indicator (display) cable to the correct terminals in the junction box. This should match the manufacturer’s connection diagram. The load cells will have corresponding switches that should be left in the ON position.

- Zero the indicator before placing the test weights over each load cell corner.

- Place the test weight first on a single corner, and record its indicated weight. Then place the test weight in the center of the measurement platform and record the indicated weight. Repeat both steps for each corner. (It is best to use a test weight that is between 20-25% of the device’s full-scale capacity. Test weight sizes depend on how many load cells are in the measurement system; therefore, verify these quantities with the instruction manual.)

- Compare each corner load cell’s measurement to its value when the weight is at the center. Locate the device that is measuring the largest difference between these values. Adjust its corresponding potentiometer until its indicator matches the reading when the weight is at center placement. This adjustment is the actual “trimming”. Note the sign conventions for junction boxes sold through Tacuna Systems are typically counterclockwise (+ increase) and clockwise (- decrease).

- Repeat Step 5 with each load cell corner, adjusting their potentiometers to equalize their values to the center measurement. Continue until all readings meet the required tolerance. Check multiple times for repeatability.

- Cover the hardware properly with the shell or box provided by the manufacturer. Verify that the device is properly sealed to prevent environmental damage.

Trimming the Load Cells by Sections

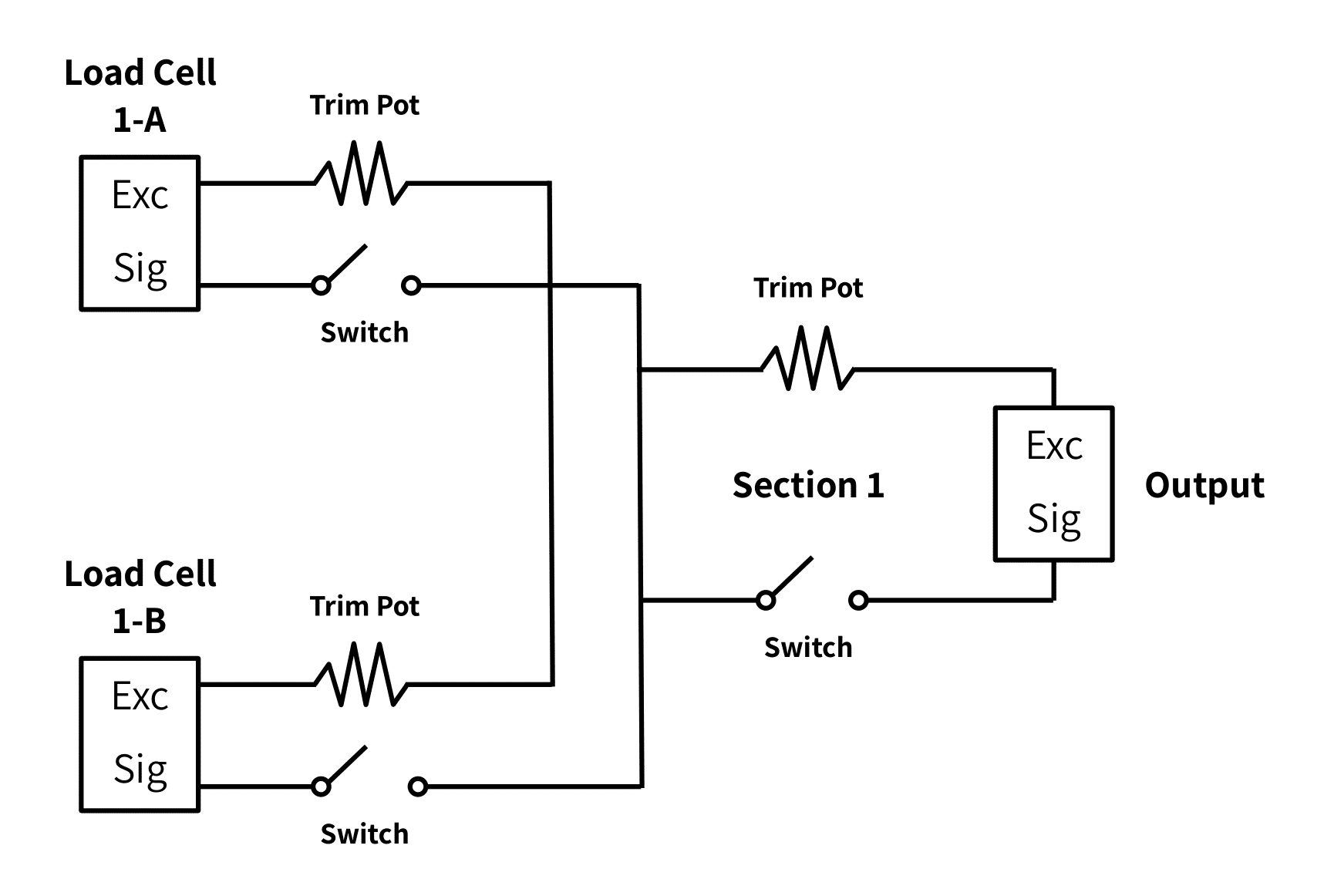

If there is an even number of load cells, they can be trimmed in pairs. The process is similar to that of trimming individual load cells described above. To trim your system this way, follow the procedure below, referring to the figure.

The Steps:

- Again, ensure that the resistance of each load cell’s potentiometer is correct, and adjust for any discrepancies. Connect each load cell to the junction terminals in the same way as with individual trimming.

- While each individual load cell has a corresponding dipswitch within the junction box, each pair or section also has a switch. The OFF switch will disable the section, while the ON setting will enable the section to measure. Enable Section 1, then enable load cell 1-A. Be sure to disable all other load cells. Place the test weight overload cell 1-A and then over the center of the platform. Record the indicated weights.

- Next, enable load cell 1-B and disable the rest. Record the indicated weight for both that corner and the center of the platform.

- Adjust the potentiometer of the individual load cell with the lowest indication to match the center reading. If the indicated weight measurement of a corner is higher than that of the center, decrease it by adjusting its corresponding potentiometer.

- Repeat these steps for the remaining load cell pairs.

- Now enable one section at a time (sections 2, 3, etc.) while keeping the remaining sections disabled. Zero the indicator and place the test weight over each section, and then the platform’s center point. Start at the section with the lowest indicated weight compared to the center. Adjust that section’s potentiometer to trim it to that of the centered measurement.

- Repeat for every section until the readings are within the necessary tolerance. Perform Steps 6-7 several times to ensure that the results are repeatable.

A Comparison of Junction Boxes

This section describes Tacuna’s product offering of load cell junction boxes.

| Product | # of Cells Summed | Type of Trim | Chassis | Standard Features | Variations |

| ANYLOAD J04EA-16 J04SA-16 J-BOX | 2 – 4 | Excitation: 350-Ω LC: 2.3% trim 700-Ω LC: 1.3% trim 1000-Ω: 1% Signal: 350-Ω LC: 3.6% trim 700-Ω LC: 6.3% trim 1000-Ω: 7% | Cast aluminum; IP67 | Pre-installed breather to prevent damage | Motherboard only option |

| ANYLOAD J04ES J04SS | 2 – 4 | Excitation and Signal; same limits as above | Stainless steel; IP65 | Lightning-protected electronics (“-II” model number extension) Motherboard only option for base and “-II” models | Lightning-protected electronics (“-II” model number extension) Expansion port to connect with other boxes plus lightning-protected chassis (“-E” extension) Smaller enclosure (“-FS” extension) Motherboard only option for base, “-II” and “-E” models |

| ANYLOAD J04SP | 2 – 4 | Signal Only: 350-Ω LC: 3.6% trim 700-Ω LC: 6.3% trim 1000-Ω: 8% | Fiberglass-reinforced polyester; IP67 | Gore Breather Vent Lightning protected electronics Expansion port to connect with other boxes | |

| ANYLOAD J06ES J06SS | 2 – 6 | Excitation and Signal; same limits as ANYLOAD J04EA-16 | Stainless steel; IP65 | Accommodates parallel load cell connections Independently adjustable potentiometers | Lightning protected electronics (“-II” model number extension) Motherboard only option for base and “-II” models |

| ANYLOAD J06S-E-21-MB | 2 – 6 | Signal Only: 350-Ω LC: 3.6% trim 700-Ω LC: 6.3% trim 1000-Ω: 8% | None (board only); IP67 (conformal coated board) | Lightning protected electronics Expansion port | |

| ANYLOAD J08ES J08SS | 2 – 8 | Excitation and Signal; same limits as ANYLOAD J04EA-16 | Stainless steel; IP65 | Independently adjustable potentiometers | Independently adjustable resistors |

| ANYLOAD J08SP | 2 – 8 | Signal Only: 350-Ω LC: 3.6% trim 700-Ω LC: 6.3% trim 1000-Ω: 7% | Fiberglass-reinforced polyester; IP67 | Gore Breather Vent Lightning protected electronics Expansion port to connect with other boxes | |

| ANYLOAD J12ES J12SS | 2 – 12 | Excitation and Signal; same limits as ANYLOAD J04EA-16 | Stainless steel; IP65 | Independently adjustable potentiometers | Lightning protected electronics (“-II” model number extension) Motherboard only option for base and “-II” models |

Conclusion

Large-scale and complex weighing systems require the use of multiple load cell devices to produce accurate measurements. Load cell summing and junction boxes properly combine their multiple signals into a useful digital output to display, store, or control complex systems.

To ensure the quality of load cell measurement data delivered to operators, the individual load cells must be properly trimmed. The trimming process equalizes the output from multiple individual load cells into a single, accurate, output. Load cell trimming guarantees the correct measurements, regardless of where the weight is on the scale.

If your application uses Tacuna Systems’ product line and you have any questions about the trimming process for your individual case, please contact Tacuna Systems customer service.

References

ANYLOAD Junction Box Manual, Q-YZ Manual-JB-J12ES-V1.2, https://tacunasystems.com/documents/J12ES-J12SS-junction-box.pdf

Measurement and Instrumentation in Engineering: Principles and Basic Laboratory Experiments,1st Edition, Francis S. Tse, Ivan E. Morse

Resistor Guide, your guide to the world of resistors: Trimpots http://www.resistorguide.com/tag/trimpot/

Load Cell and Weigh Module Handbook: A Comprehensive Guide to Load Cell Theory, Construction and Installation, Rice Lake Weighing Systems