Wireless data transmission has become the norm in modern times, especially with the growth of the Internet of Things (IoT). With the improvement of communication protocols, and in turn connection reliability and speed, wireless technology is without a doubt the new backbone of data-driven applications. And load cell applications are no exception. This article briefly describes scenarios where wireless load cell data transmission solves key challenges. It concludes with a brief description and comparison of the wireless load measurement solutions Tacuna Systems provides.

Where to Go Wireless

The best answer to the question, “where could I incorporate wireless load-cells?” is anywhere that has conventional wired load cells. However, there are places where wired load cells are completely impractical.

Where Mobility is Part of the Job

Often with large-scale or distributed systems, operators must collect measurement data while maneuvering around distances or large obstructions. Wireless receivers or indicators give them access to real time data from any such location. This improves the efficiency over a central, wired collection site, especially when calibrating and testing load cells or performing routine maintenance.

Where Flexibility of Interfaces is Key

Conveniently, smart phone and tablet apps exist that receive wireless load cell data transmission. These apps not only display this data in a user-friendly format, but can also process it further. This can streamline operating procedures considerably. Easier displays and operating procedures in turn simplify operator training and all of these add up to considerable operating cost savings.

To Reduce Installation and Maintenance Cost and Complexity

Without a doubt, system installation and servicing create the most significant expenses for complex load cell or strain gauge measurement systems. This is especially true of transmission cabling installation from the sensors to the user interface. Proper installation of transmission cables and wiring harnesses can be tedious; improperly installed cables can become a safety risk by entangling equipment or personnel. Installation expenses only increase when wiring must be underground or aerial to avoid environmental hazards. Also, long wiring runs degrade signals and require additional filters and repeaters.

Wireless load cell signal transmission gets rid of these issues. It eliminates wiring and signal boosting material costs, avoids labor-intensive cable positioning, and as mentioned before, permits the consolidation of user interfaces, further decreasing installation complexity and cost.

When it comes to maintenance, wireless systems are also the clear winner. Wireless measuring systems only require access to specific measurement locations or nodes, potentially saving thousands on inspections and upkeep.

Where Safety is an Issue

Wired load cell connections can be challenging, if not impossible, in environments that have rugged terrain, moving parts or are hazardous to humans. In these cases, products like the wireless readout in Figure 2 make measurements far more accessible. Where moving parts are involved (such as cranes), this readout gives operators real-time measurement data at a safe distance. Likewise, weighing structures with tight clearances can make the space needed for safe wiring impossible. In these applications, wireless communication between deployed load cells and this readout avoids potential fires or measurement errors from pinched or frayed wires in tight spaces.

Examples of Wireless Load Cell Applications

Distance Applications and Wireless Telemetry

Telemetry, or the transmission of data or signals over long distances, is used to monitor remote, inaccessible locations. Wireless telemetry allows operators to gather accurate measurements in very large or distributed environments.

The advantages to wireless communication are many when a measurement application is at a remote distance. Unlike traditional wiring, wireless telemetry is less impeded by physical barriers. Signals can go through walls, piping, ducts, and most other materials with relatively little interference. Also, as mentioned above, wireless systems only require access to specific measurement locations or nodes. This greatly lowers the complexity of installing and maintaining systems applied over large-scale surfaces or regions of land.

For long-term civil structures such as bridges and buildings, remote monitoring of the structure’s loading can help pinpoint potential damage. In the past, engineers had relied on visual inspections to detect structural damage. However, these visual inspections are only as effective as the inspection frequency and the inspector’s subjective judgment. The use of grids of wireless load cells or strain gauges eliminates much of this human effort and potential error. These grids create a matrix that allows real-time monitoring of large surfaces (see figure below). This in turn leads to earlier and faster detection of strain localization and prediction of structural damage. This US Department of Energy report predicts a tenfold return on investment of predictive maintenance.

One can easily conclude from this that wireless automation reduces inspection costs and risks associated with accessing large structures. Automated, wireless monitoring of structures can ultimately improve the life of the structure, regulate scheduled maintenance, and reduce inspection time.

Dynamic and Moving Systems

When the measured object or system is static, connections to the measuring system are simple. However, if the measured object is mobile or dynamic in nature, monitoring becomes an increasingly complex challenge. Load cell wiring can interfere with the motion of these systems and can be damaged.

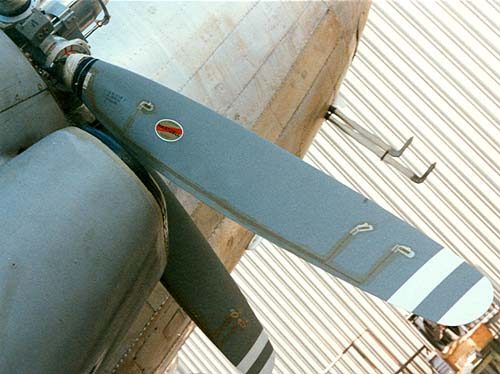

Some examples of mobile applications using load cell measurement are cranes, forklift scales, and other hoisting applications. Propellers, wind turbine blades, pumps, rotors, and engines are common applications of fast moving parts.

Rotating Systems

Any rotating system that requires measurement creates a challenge when measuring.

Slip rings are electromechanical devices that transmit an electrical signal from a rotating system to a fixed system. Rotating objects cannot be restrained by connected wiring so a slip ring is used to transfer both power and data. Slip rings simplify systems and eliminate wired connections that could experience damage during operations.

These devices do require frequent maintenance and struggle with reliability. Because they are subject to constant movement, slip rings need constant upkeep. Without proper maintenance, they can degrade due to contaminants and constant abrasion. Slip rings are difficult to repair and usually require replacement if damaged.

Reliability aside, slip rings are often preferred for high-speed or high-rpm data transmission. Market solutions exist that fully replace rotating gauges and load cells with wireless transmitters; however they become less accurate as speeds increase. This makes them impractical to use on applications like engines. Wireless technology is always improving; however slip rings remain the most feasible solution.

Hoisted Applications

Cranes and other hoists are in constant movement during standard operations. At the same time, there is the need to monitor the loads they bear, for safe operations. Using wireless technology for these applications is especially useful around construction, as the load measuring fixtures are in constant movement.

Two load cell types used for these applications are crane scales and load pin load cells. The section below, “Specific Hoisting Applications,” describes these devices.

Dangerous Environments

Many measurement applications exist that have inherent risk due to their location. For example, mining, oil refineries, furnaces, offshore and on-land oil rigs, and nuclear reactors may incorporate load cells in their monitoring systems. These rely on accurate data. However, their higher than normal radiation, toxic or explosive atmospheric conditions, extreme temperatures, or submersed implementation creates risk to technicians and operators. As mentioned earlier, eliminating cable runs in these applications reduces installation, inspection, and troubleshooting time. This in turn reduces the duration of a technician’s exposure to these dangerous conditions. That is, while hazards are unavoidable, in these applications, wireless telemetry eliminates failure points and maintenance associated with wired connections.

Internet of Things (IoT)

The Internet of Things is simply a concept – one where the devices with which we interact have wireless connections to internet apps that improve their efficiency, safety, or user experience. These devices can be consumer in nature or part of a business or manufacturing process (like the earlier examples in this section). Smart transportation systems, modern healthcare, and many security applications rely on IoT technology. What these devices all have in common is the use of wireless sensors to collect and report data to their apps. These apps process the data to determines some course of action by a consumer-oriented or manufacturing control system. And, full circle, this system functions to improve efficiency, safety or user experience.

The applications above could be considered part of the Internet of Things. However the IoT is broader than just these. For a more detailed overview of the IoT, see the article, The IoT and Sensors: A Quick Overview.

Implementation of Wireless Load Cells

As described above, wireless load cells can provide many advantages over wired connections. But there is more than one way to implement wireless transmission. The three main ones are:

- Integrated wireless transmitters internal to load cell devices paired with any receiver,

- Integrated wireless transmitters internal to load cell devices paired with a dedicated wireless indicator such as the ANYLOAD 805HP-WL in Figure 1, and

- Wireless bridges that act as the transmitter and receiver between any current or customized measurement system. These devices replace intermediate lengths of wire. This concept is covered in the next section.

The good news is that there are quite a few product options that can add wireless connections to most load cell applications.

Products that Convert Conventional Load Cells to Wireless

Often the easiest way to implement wireless measuring is to outfit existing analog load cells with wireless transmission. This provides minimal up-front investment in new measurement devices. It also upgrades existing systems with minimal impact to the load cell frame or fixture.

With Tacuna Systems’ TBX Wireless Load Cell Bridge, any standard load cell application can be converted to wireless. The TBX wireless bridge replaces any physical wire or cable connection between load cells and measurement indicators. It easily retrofits to existing systems but it can also be part of new measuring system deployments. Likewise, our ANYLOAD WL-RF-17 and WL900 Transmitter/Receiver products function similarly.

The transmitter on all three products connects directly to the load cell’s output wiring. This converts any load cell, scale, pressure sensor, torque sensor and resistive sensor to wireless.

The receiver device for the TBX transmitter can be one of several configurations. Option one is to pair its transmitter with its receiver connected to a standard weight indicator. The second option is to pair its transmitter with the TBX app on any smartphone or tablet. Finally, the TBX-T transmitter can pair directly with software on a device (tablet or computer) with compatible reception; this makes storing and displaying data more user-friendly.

The WL100 receiver can collect data from multiple sensors. It connects to a computer via USB that must run the WL100 app to collect and display the load cell data. The WL900 receiver interfaces exclusively with the ANYLOAD 808 series wireless displays discussed below.

Both the TBS and WL100 devices use Bluetooth low energy 2.4 GHz radio connections. The WL900 uses a 900MHz transmission frequency.

Products for Hoisting Applications

As mentioned before, wireless technology is highly advantageous for cranes and other hoists, as they are in constant motion during use.

Tacuna Systems offers the ANYLOAD 110ES-WL and ANYLOAD 110ES-WL-HP wireless crane scales with standard wireless transmitters for measuring crane loads of up to 100 tons. Their salt and waterproof stainless steel casting and silicone-enclosed antenna withstand harsh conditions like deep sea fishing. But they are also ideal for other hoisting and lifting applications. Other hoisting products in our shop include the ANYLOAD 110RH-WL Wireless Alloy Steel Tension Link, with capacities up to 50 tons, and the ANYLOAD OCSD Wireless Dynamometer, with capacities of up to 200 tons. Other than range of capacities, these three products differ in their environmental rating; the 110ES-WL and 110-WL-HP are IP68/69K, the 110RH-WL is IP67, and the OCSD is not rated. The ANYLOAD 110 series wireless crane scales pair with the ANYLOAD 805HP-WL Wireless Hand Held Indicator; the OCSD pairs with the ANYLOAD P180, P380, and P580 Wireless Displays.

Wireless Indicators and Displays to Improve Productivity

For many measuring applications, wired connections are still viable. However, even for these, mobile readouts can increase efficiency or improve ease-of-use for operators. In these cases, Tacuna Systems recommends the use of a wireless display or indicator as the output interface.

For high visibility displays in stationary locations, we offer ANYLOAD’s 808 Series LED wireless load cell indicators. These include the 808AH-WL, 808BH-WL, and 808CH-WL. These come with the WL900 Transmitter/Receiver, to connect to any wired load cell.

Handheld indicators are are simple, single-point, devices that interface with most load cells. Tacuna Systems offers the ANYLOAD 805HP-WL Wireless Hand Held Indicator and the ANYLOAD P180 Wireless Display. These pair with the wireless crane scales listed in the table titled “Products for Hoisting Applications”.

A Comparison of Tacuna Systems Wireless Products

Products that Convert Conventional Load Cells to Wireless

| Feature | Models | ||

|---|---|---|---|

| ANYLOAD WL-RF-17 | ANYLOAD WL900 | TBX Wireless Bridge | |

| Compatible With | all strain gauge load cells, all brands |

all weight indicators/brands (to connect to ANYLOAD 808 Series displays) |

all strain load cells, all brands |

| Display Type | This transmission module that connects to load cell output cables pairs with the 805HP-WL display |

LED | Receiver connects via load cell connectors to standard display, or can display to mobile app (receiver not needed) |

| Frequency of Transmission | 433Mhz or 915Mhz | 900MHz (US / CAN / AUS / EU) |

Bluetooth 4.0 Low Energy 2.4 GHz |

| Approvals | FCC, IC, C-Tick | CE, RED, RoHS, MD | |

| Display Digits | None | Six; 0.4″ (10mm) high, 7-segment | None |

| Communication Ports | Transmitter: load cell pin connector | 3 independent serial ports: RS232, RS422/RS485, 20mA current loop |

Transmitter: load cell pin connector Receiver: RS232 for communicating transmitter battery status |

| Enclosure Material | PVC | Stainless Steel | Metal enclosure |

| IP Rating | IP67 | 65 | Moisture resistant |

| External Power Supply | 3 x AA Alkaline Batteries (included) | Input: 100-240VAC, 0.6A, 50/60Hz / Output: 12VDC, 2.0A, 25W wall adaptor |

Transmitter: 3 x AA battery, Li-Ion / Li-Po 3.7V Receiver: 5 – 10 VDC supplied by the connected load cell indicator |

| Battery Life | <100 hours | <100 hours | Transmitter: 1000 hours |

| Wireless Range | 75m (unobstructed) | 100m (indoor); 300m (unobstructed) |

20m |

| Working Temperature | -20°C to 70°C / -4°F to 158°C | -40°F to 120°F (-40°C to 50°C) | -40°C to 85°C |

| Dimensions (mm) | 100 H x 100 W x 40 D | 144 W x 142 H x 44 D | 86 x 47 x 12 (without housing) |

| Dimensions (inch) | 3.94″ x 3.94″ x 1.57″ | 5.7″ W x 5.6″ H x 1.7″ D | 3.2″ x 2″ x 0.5″ |

| Total Weight | 1.1 kg (2.42 lbs) | 1.0 kg (2 lbs), including wall adaptor | |

Products for Hoisting Applications

| Feature | Models | |||

|---|---|---|---|---|

| ANYLOAD 110ES-WL | ANYLOAD 110ES-WL-HP | ANYLOAD 110RH-WL | ANYLOAD OCDS | |

| Capacities | 1t-100t | 1t – 100t | 0.5t – 50t | 1t-200t |

| Accuracy | 1:6000 |

1t-10t: 1:5000 |

0.5t, 1t, 5t, 10t, 50t: 1:5000 |

1:2000 to 1:3000 |

| Material | Cast Stainless Steel | Cast Stainless Steel | Powder Coated Alloy Steel | 1-5t: Aluminum >10t Alloy Steel |

| IP Rating | IP68/69K | IP68/69K | IP67 | none given |

| Receiver Options | ANYLOAD 805HP-WL | ANYLOAD 805HP-WL | ANYLOAD 805HP-WL | ANYLOAD P-Series |

| Transmission Range | <30m | 30-75m (depending on frequency) | 30-75m (depending on frequency) | <30m |

| Battery Life | <8 hour | <100 hour (max at 20 C and at the lowest power set up) |

<100 hour (max at 20 C and at the lowest power set up) |

<50 hour |

Wireless Indicators and Displays

| Feature | Models | ||||||

|---|---|---|---|---|---|---|---|

| ANYLOAD 805HP-WL |

ANYLOAD P180 |

ANYLOAD P380 |

ANYLOAD P580 |

ANYLOAD 808AH-WL |

ANYLOAD 808BH-WL |

ANYLOAD 808CH-WL |

|

| Compatible With | all load cells, all brands (up to 16 load cells w/Junction Box & Wireless Transmitter) |

ANYLOAD OCSD Dynamometer |

ANYLOAD OCSD Dynamometer |

ANYLOAD OCSD Dynamometer |

all load cells, all brands via WL900 transmitter/receiver (included) |

all load cells, all brands via WL900 transmitter/receiver (included) |

all load cells, all brands via WL900 transmitter/receiver (included) |

| Display Type | LCD | LCD | LCD | LCD (and Fujitsu FTP-680 thermal printer) |

LED (with brightness control and 120° viewing angle) |

LED (with brightness control and 120° viewing angle) |

LED (with brightness control and 120° viewing angle) |

| Display Number of Digits | 6 | 5 | 5 | 5 | 6 | 6 plus semaphore | 5 |

| Display Digit Height | 17mm / 0.66in | 12mm/0.47in | 25mm/1in | 25mm/1in | 125mm/5in | 125mm/5in | 62.5mm/2.5in |

| Display Backlight | Toggle on-off (battery saver) |

Yes | Yes | Yes | NA | NA | NA |

| Units | kg, g, t, lb, klb, N, kN, oz or user-defined |

kg/lb | kg/lb | kg/lb | |||

| Enclosure Material | ABS | Mild steel powder coated NEMA 4 |

Mild steel powder coated NEMA 4 |

Mild steel powder coated NEMA 4 |

|||

| IP Rating | 65 | 65 | 65 | 65 | |||

| Power Source | 3 x AA Alkaline batteries | USB connection or rechargeable lithium battery (included) |

4 x AA (rechargeable) | Ni-H battery | Input: 100-240VAC, 1.2A, 50/60Hz Output: 12VDC, 5.0A, 60W encapsulated |

Input: 100-240VAC, 1.2A, 50/60Hz Output: 12VDC, 5.0A, 60W encapsulated |

Input: 100-240VAC, 1.2A, 50/60Hz Output: 12VDC, 5.0A, 60W encapsulated |

| Battery Life | <100 hours | 50 hours | 50 hours | 50 hours | NA | NA | NA |

| Frequency | 900MHz | 2.4GHz (two-way) | 2.4GHz (two-way) | 2.4GHz (two-way) | (per WL900) | (per WL900) | (per WL900) |

| Wireless Range | 75m unobstructed |

30m | 30m | 30m | (per WL900) | (per WL900) | (per WL900) |

| Connectivity | USB port to PC | RS232 to printer; other peripherals | USB and RS232 |

3 serial ports for RS232, RS422/RS485, & 20mA current loop (auto-learn baud rate & protocol) and RF Wireless link (both transmit and receive) |

3 serial ports for RS232, RS422/RS485, & 20mA current loop (auto-learn baud rate & protocol) and RF Wireless link (both transmit and receive) |

3 serial ports for RS232, RS422/RS485, & 20mA current loop (auto-learn baud rate & protocol) and RF Wireless link (both transmit and receive) |

|

| Working Temp | -20° to 70° C -4° to 158° |

-20°C to 60°C -4°F to 140°F |

-20°C to 60°C -4°F to 140°F |

-20°C to 60°C -4°F to 140°F |

-40°F to 120°F -40°C to 50°C |

-40°F to 120°F -40°C to 50°C |

-40°F to 120°F -40°C to 50°C |

| Dimensions (mm) | 170 x 98 x 34 | 28 x 70 x 90 | 220 x 105 x 50 (handheld) |

220 x 130 x 92 | 658 x 348 x 149 | 918 X 348 X 149 | 353 x 191 x 116.8 |

| Dimensions (in) | 6.7 x 3.9 x 1.34 | 1.10 x 2.8 x 3.54 | 8.7 x 4.1 x 2 | 8.7 x 5.1 x 3.6 | 25.9 W x 13.7 H x 5.9 D | 36.1 W x 13.7 H x 5.9 D | 13.90 x 7.52 x 4.60 |

Conclusion

With the rise in cloud computing, internet incorporation, and big data analysis, wireless systems are increasingly critical to business innovation. As the reliability and speed of wireless technology improves, companies will continue to swap physical connections for digital and wireless.

Wireless transmission of data in load cell measurements likewise continues to improve. For example, wireless technology solutions now exist for most load cell applications. Moreover this technology has many advantages including allowing operators to gather accurate, real-time measurements in distant, dynamic or dangerous environments. It reduces the management of cabling for weighing applications on moving systems like wind turbines, in fixtures with tight tolerances where wires could become damaged, or in inaccessible environments. Operators also have increased mobility and maneuverability, which improves their speed and job efficiency. Utilizing wireless load cells can ultimately improve safety for operators and technicians, and reduce the cost of installation and maintenance.

References

- Measurement and Instrumentation: Theory and Application, Alan S Morris, Reza Langari

- Measurement and Instrumentation in Engineering: Principles and Basic Laboratory Experiments,1st Edition, Francis S. Tse, Ivan E. Morse

- Civil Structure Strain Monitoring with Power-Efficient,High-Speed Wireless Sensor Networks”, J.H. Galbreath, C.P. Townsend, S.W. Mundell, M.J. Hamel

- B. Esser, D. Huston, Ph.D., S.W. Arms, 4th Int’l Workshop on Structural Health Monitoring Stanford University, Stanford CA, Sep, 2003

- Large-Scale Surface Strain Gauge for Health Monitoring of Civil Structures, Simon Laflamme, Matthais Kollosche, Guggi Kofod, Smart Structures and Materials, 2012

- Douglas DC-3 Re-engine STC Project