Like other inventions, signal amplifiers were created out of an inherent need to solve a problem—boosting a weak and often noisy signal. Strain gauge load cells, by their nature, produce such a signal. As we showed in our article, The Versatile Strain Gauge Load Cell, these devices create a voltage difference across the two outputs of a Wheatstone Bridge, which is inherently very small (in the order of millivolts). Add to this the fact that they often function in environments that contribute noise to that small signal. Wide temperature variations, electromagnetic interference, and other harsh conditions all degrade load cell outputs. These factors make amplifiers and signal conditioners essential companions for load cells in weighing systems.

This article explains the various forms of signal conditioning. But first, it provides a brief background on analog and digital signals and the process of converting between them, since analog-to-digital and digital-to-analog conversion are fundamental to signal conditioner technology. Finally, it concludes with a comparison table and buying guide to help the reader select the right product.

Analog and Digital Signals: How are they Related?

Historically, signal processing has been analog-based, as most load and force measurement sensors or transducers generate an analog signal. This has changed with the emergence of small computers, wireless Internet, and ever-evolving processing speed. Modern-day, real-time signal processing systems are now almost entirely digital and software-based.

What is the practical tradeoff? Whereas analog processing is instantaneous and cheaper, digital processing often delivers more accurate results. Digital signal conditioning also offers easier troubleshooting, adjustment, and tuning. And with modern computing, their delay is negligible. However, signal conditioning systems do incorporate both processing types, especially when cost is a factor.

Analog-to-Digital Conversion

Analog-to-digital converters, or ADCs, appear in applications where altering or manipulating digital signals to get the desired output is simpler. Familiar examples are music recording or photography, where light or sound is converted to digital signals. The digital format gives tremendous flexibility in shaping these industries’ creations. Similarly, ADCs are useful in converting load cell measurements into a digital format.

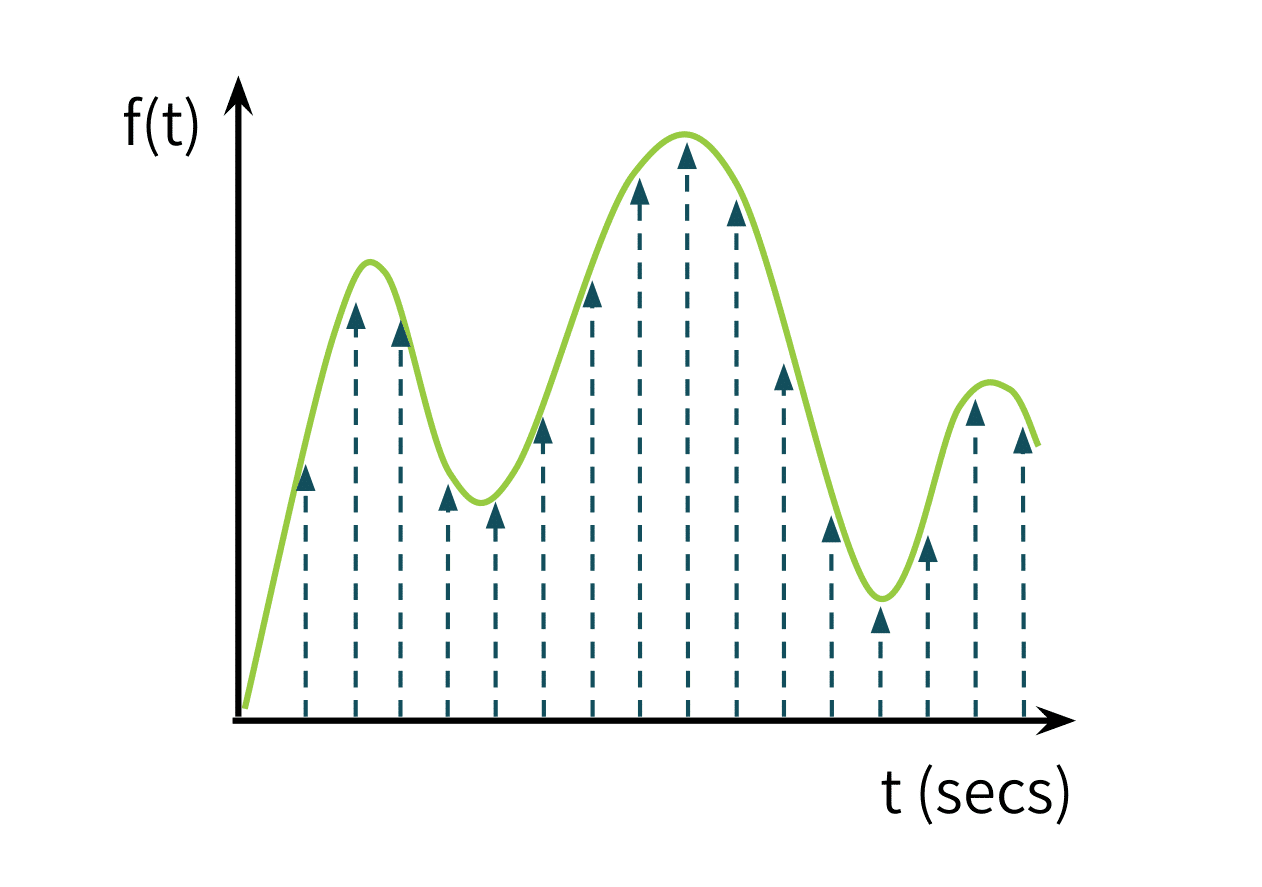

ADCs sample the amplitude of a signal at discrete points in time. They then convert each sample to a digital signal representing its magnitude. The arrows in Figure 4 below represent each moment data is sampled. The analog input, shown as the light green curve, is a constant stream along the time axis. The output samples are digitized into a stream of bytes.

Digital Signal Accuracy and Resolution

Signal sampling limits the allowable bandwidth, or range of frequencies that can be accurately represented by a digital signal. This is the “Nyquist limit,” and is equal to half the sampling frequency. That is, if a ADC samples at a rate of 120 samples per second, the highest input frequency that the ADC output can accurately represent is 60 Hz. Because the digital output is no longer a continuous signal, this sampling rate becomes extremely important. The higher the sampling rate, the better the digital signal approximates the analog one.

The number of digital bits used to represent the amplitude is also important. A bit is a binary digit, or logical value, that represents some unit of information. Each single bit represents one of two states (on-off or high-low). An analog-to-digital converter will typically use at least eight bits, with more bits increasing the converter’s signal accuracy or resolution. For example:

28 = 256, so the resolution of the 8-bit sample is 1 part of 256

212 = 4096, so the resolution of the 12-bit sample is 1 part of 4096

The more bits, the greater the dynamic range (how small or large a signal it can measure) and the lower the quantization error (the difference between the analog input and its digital approximation).

Signal Conditioners: What are they and What do they Achieve?

Electrical noise (from high power lines, for example) can easily overwhelm a weak load cell output signal. A connected control system or scale readout can’t function properly with that raw signal. As mentioned before, this makes signal conditioning essential.

Signal conditioning is the process of converting the raw load cell electrical output to useful data. It can encompass one or more of these functions: amplification, attenuation, isolation, linearization, bridge completion, or other types of filtering.

When signal conditioning is part of a measuring system, its output will have these three qualities:

- It will be large enough to detect (through amplification),

- It will be free of noise/unwanted frequencies (through filtering), and

- It will be in the appropriate signaling format.

(1) Amplification: Analog and Digital

How does an instrumentation amplifier change the load cell’s raw signal? It amplifies the load cell output from 0~36 mV to either 0-10V or 4-20mA. Amplifiers typically use DC power (24V) and can drive ~ 300Ω load cells connected directly. Many handle one or two devices alone, but can connect to more load cells at a time via junction boxes. (See Load Cell Summing: Junction Boxes, Signal Trim and Excitation Trim.)

Analog Amplifiers

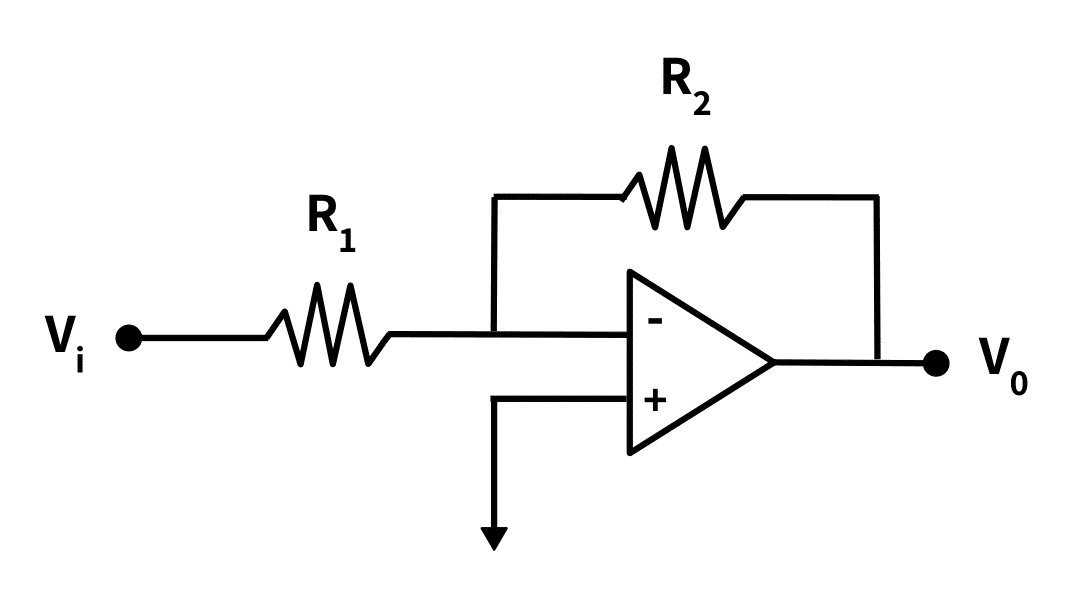

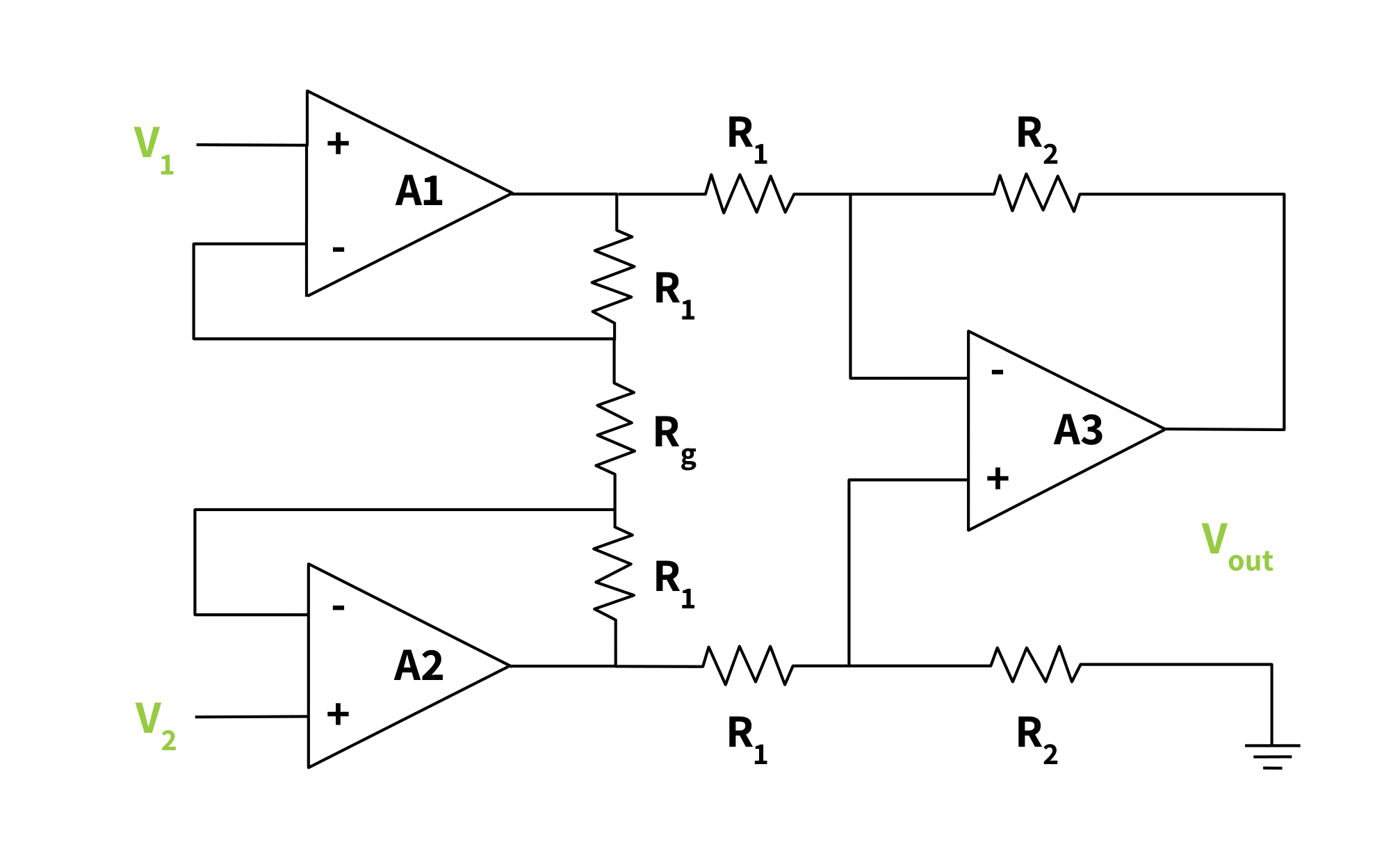

Typically analog amplification happens through an operational amplifier, also known as an op-amp. Op-amps are electronic devices with two input terminals: the inverting and non-inverting ends. As Figure 2 shows, the raw signal connects to the inverting side with one resistor; the non-inverting side connects to ground. A feedback path connects from the output terminal, with a second resistor, to the inverting terminal.

The output signal is related to the input voltage through the equation below. Therefore the amount of amplification is based on the values of R1 and R2.

Operational Amplifier Relational Equation

\(V_{0}=\frac{R_{2}V_{i}}{R_{1}}\)

Instrumentation amplifiers, such as the ones used with load cells, require the amplification of extremely low-level signals. They may combine up to three op-amps to increase the output amplitude to the needed level.

Certain applications, like accelerometers, require the amplifier to have a high-frequency response, to prevent distortion.

Digital Amplifiers

Digital amplifiers, as the name implies, increase the magnitude of a digital signal rather than an analog one. When using these, the load cell’s analog output is converted to digital through an ADC before amplifying the signal. The digital amplifier then multiplies the sampled values by a fixed constant to amplify the signal.

(2) Attenuation

Attenuation is the opposite of amplification. Instead of increasing the signal amplitude, attenuation decreases it. This is necessary when the voltage is beyond the range of the analog-to-digital converter. Like digital amplification, a digital attenuator multiplies the digital signal by a fixed constant, mathematically changing the output’s amplitude.

(3) Isolation

Signals outside of the voltage range of an input device can cause equipment damage and hazards to operators. Isolation is common when there is a need to protect the measurement system from incidental voltage spikes. It also breaks ground loops, blocks surges, and rejects high voltages.

Various methods exist for isolating voltages, including creating physical barriers for signals, and using isolation amplifiers. The specific application, and the driving reasons for the need for isolation determine the method used.

(4) Signal Linearization

Signal linearization converts a transducer’s non-linear output into a linear signal to more accurately represent the measured value. This step is important when the relationship between a sensor’s input and output isn’t perfectly proportional. Devices that measure temperature, such as thermocouples, often need linearization to produce accurate readings across their full range.

Linearization can be done using analog signal conditioning, such as operational amplifiers, or through digital processing in software or microcontrollers.

(5) Bridge Completion

Bridge completion forms a four-resistor Wheatstone bridge when using a quarter or half-bridge sensor. The Tacuna Systems precision strain gauge amplifier/ conditioner provides this completion with high-precision resistors. This device detects small voltage changes across the active sensors connected to it.

(6) Signal Filtering

Signal filtering removes unwanted frequencies from a raw signal. An example of these unwanted frequencies is the low frequencies generated by high-power lines. A weigh system designer can filter them out to measure only the higher-frequency portion of a load cell output.

Signal filtering is possible both digitally and through analog circuits. The most common filters are high-pass, low-pass, band-pass, and notch filters. As their names suggest, these filters allow high, low, mid, or only high/low-frequency signals from the raw source signal to pass, while denying the rest. The range of permitted frequencies is called the “passband,” while the denied frequency range is called the “stopband.”

A passive filter uses only passive elements such as resistors, capacitors, inductors, and transformers. Therefore, it does not require an external power source. It has the added advantage of having a more stable output than an active filter.

An active filter, on the other hand, includes active components such as amplifiers and therefore requires a power source. Active filters can provide signal gain and better control over filtering characteristics, making them useful in many precision measurement systems.

How to Choose and Connect a Load Cell Amplifier or Conditioner

While choosing the appropriate load cell model for an application is important, selecting a signal conditioner is equally critical. The wrong amplifier or conditioner can distort the load cell measurements. Likewise, using the load cell amplifier properly is essential for high-quality, accurate readings.

For best results in using signal conditioners, follow these three guidelines.

- Always follow the manufacturer’s operation manual,

- Ensure that operators receive proper training prior to installation,

- Contact your vendor should questions or concerns arise while operating products.

Tacuna Systems is readily available to answer any design or implementation questions regarding our amplifier and conditioner products. See our “Featured Customer Projects” section to see the scope of projects we’ve assisted with. (See especially, Next-Gen Transmissions for High-Performance Hybrid Cars, and Measuring Contact Forces on Soft Materials for Medical Robotics and Other Applications for test projects using the Tacuna Systems EMBSGB200 amplifier.)

Connecting and Installing a Load Cell Amplifier

The following is an example of connecting an ANYLOAD load cell amplifier:

- The input voltage should connect to 24V DC power and the ground terminal to the ground.

- The load cell connects to the amplifier through the positive(+) and negative(–) excitation terminals, and to the positive(+) and negative(–) output mV signal terminals.

- The output from the amplifier connects to either the current output for a signal of 4~20mA or a voltage output signal of 0~10V.

- To calibrate the conditioner, remove any load from the transducer and adjust the variable resistor to an output of 0V or 4mA. To calibrate the full span, place the entire load on the transducer and adjust its variable resistor to an output of 10V or 20mA.

The load measurement system will be fully functional and ready to operate. Re-calibrate the device frequently and whenever the output readings change, or the signal is abnormal. Most load cell signal conditioners should operate from 10°C – 40°C, or 15 – 100°F, and below 90% relative humidity. However, always review the product specs before operating in high and low-temperature environments.

Lastly, contact the supplier for setup assistance, calibration assistance, and troubleshooting.

Tacuna Systems Load Cell Amplifiers: Comparison and Buying Guide

This section provides a comparison table with each amplifier and signal conditioner product Tacuna Systems carries.

| Device | Tacuna Systems EMBSGB200-M | Tacuna Systems EMBSGB200-C | Tacuna Systems EMBSGB200-X | ANYLOAD A1A-22 | ANYLOAD A1A-D25 | ANYLOAD A2A-D2 | ANYLOAD A2P-D2 |

|---|---|---|---|---|---|---|---|

| Load Cell Compatibility | Any strain gauge type | Any strain gauge type | Any strain gauge type | Any strain gauge type | Any strain gauge type | Any strain gauge type | Any strain gauge type |

| Field Calibration Required? | No | No | No | Yes | Yes (9pt multi-section, non-linear calibration) | Yes | Yes |

| Bridge Completion | Yes: 1/4, 1/2, 3/4, and full bridge | Yes: 1/4, 1/2, 3/4, and full bridge | Yes: 1/4, 1/2, 3/4, and full bridge | No | No | No | No |

| Excitation voltage to LC | 5V | 5V | 5V | 12V | 5V | 5V or 12V (settable) | 5V or 12V (settable) |

| Input Signal | 100mVDC | 100mVDC | 100mVDC | 0mV-30mV | 0mV-30mV | 0±36mV | 0±36mV |

| Output Signal | 0-5V analog | 0-5V analog, 4-20mA | 0-5V analog or 12 bit digitized with ADC | 0-10V, 4-20mA | 0-10V | 0±10V, , 4-20mA | 0±10V, 4-20mA |

| Noise Elimination Filter | Two low-pass (corner frequency ~70Hz with 350Ω bridge or ~100 Hz with 120Ω bridge) | Two low-pass (corner frequency ~70Hz with 350Ω bridge or ~100 Hz with 120Ω bridge) | One low pass antialiasing filter; corner frequency 200Hz | ~400Hz | 2.3Hz | 16Hz | |

| Gain Setting | Discrete preset values selectable with DIP switch | Discrete preset values selectable with DIP switch | Programmable via RS232 | Potentiometer | Programmable via RS232 | Potentiometer (to adjust span) and combination of DIP switch and excitation voltage settings | Potentiometer (to adjust span) and combination of DIP switch and excitation voltage settings |

| Offset Adjustment | Potentiometer | Potentiometer | Programmable via RS232 | Potentiometer | Programmable via RS232 | Potentiometer | Potentiometer |

| Capacity | With junction box up to: 16 x 700Ω 8 x 350Ω | With junction box up to: 16 x 700Ω 8 x 350Ω | With junction box up to: 16 x 700Ω 8 x 350Ω | Single 350Ω or With junction box up to: 8 x 700Ω 4 x 350Ω | Single 350Ω or With junction box up to 4 x 350Ω or greater | Single 350Ω or With junction box up to: 8 x 700Ω 8 x 350Ω 4 x 350Ω | Single 350Ω or With junction box up to: 8 x 700Ω 8 x 350Ω 4 x 350Ω |

| Overall Dimensions | 1in x 3in x 0.5in | 1in x 3in x 0.5in | 1in x 3in x 0.5in | 3.7in x 2.5in x 1.4in | 3.7in x 2.5in x 1.4in | 4.02in x 5.0in x 1.14in | 3.9in x 2.8in x 2.6in |

| Enclosure Material | ABS (optional) | ABS (optional) | ABS (optional) | Aluminum Casting | Aluminum Casting | Aluminum Casting | PVC |

| Enclosure Ingress Protection | IP40 | IP40 | IP40 | IP66 | IP66 | IP66 | IP40 |

| Enclosure Installation | None – Tabletop or double-sided tape | None – Tabletop or double-sided tape | None – Tabletop or double-sided tape | Screw mounting holes within enclosure | Screw mounting holes within enclosure | GORE breather vent and capacitive screws | Screw mounting holes on flanges external to enclosure |

Summary

The weak load cell output signal is easily distorted by environmental noise and too small to drive a readout or control system. Therefore, accurate weigh systems incorporate signal conditioning, including amplification, filtering, and linearization. These improve signal quality to ensure precise, consistent measurements.

A properly conditioned output should be:

- Strong and stable enough for accurate processing by displays, controllers, or data systems

- In the correct format (analog or digital)

- Filtered to remove unwanted frequencies (noise-free)

To see an interesting example of our Tacuna Systems EMBSGB200 Amplifier at work, see Next-Gen Transmissions for High-Performance Hybrid Cars in our “Featured Customer Projects” section of this Knowledge Base. Also, see How the EMBSGB200 Amplifier is Shaping Innovations in Technology and Industry for other examples of how our customers have used this versatile device.

References

- Measurement and Instrumentation Principles, 3rd Edition Alan S.

- ANYLOAD A2P-D2 Load Cell Amplifier Product Manual (v1704)

- The Engineer’s Guide to Signal Conditioning, National Instruments