Continuum Robots and Tactile Sensors

Our article, Load Cells and Force Sensors in Robotics, introduces recent advancements in robotics technology through the use of load cells and force transducers. Here we continue by looking at a specific example of robotics that employs these sensors: continuum robots.

What is a Continuum Robot?

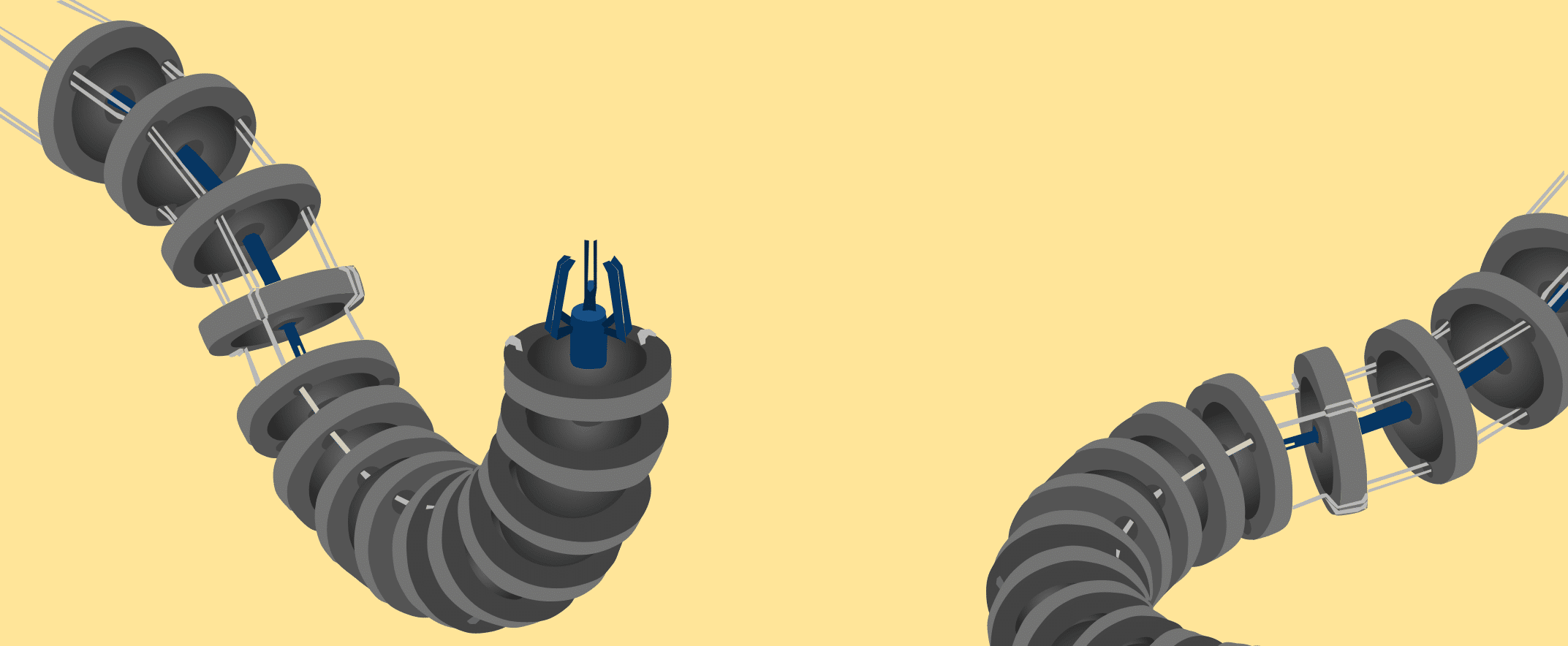

A continuum robot is a continuously curving manipulator like the arm of an octopus or the trunk of an elephant but at a much smaller scale. It is incredibly maneuverable in navigating restricted spaces without doing damage to the passage walls, materials, or tissue. Also, it may have devices attached to its end, such as a camera, grasping claw, or a cutting mechanism.[1] Some typical applications of a continuum robot are:

- Robotic surgery procedures such as endoscopy, colonoscopy, or neurosurgery;

- Hazardous operations such as bomb disposal or search and rescue at natural disaster sites;

- Actions in hazardous atmospheres such as a nuclear site;

- Maintenance applications in industrial situations where space is restricted;

- Transport mechanisms for inserting embedded sensors such as load sensors, force sensors, or tactile sensors.

Tactile Sensors vs. Other Force Transducers

Load cells/strain gauge sensors, piezoelectric force sensors, and tactile sensors have much in common. All of these sensors perform the same function of measuring force. However, they differ in the types of applications where they best serve.

The following sections quickly explain the functions of different sensors and their applications in robotics.

Load Cells/Strain Gauge Sensors

Load cells/strain gauge sensors measure force primarily through the use of strain gauges. The strain gauge is connected to a printed circuit board (PCB) that converts a mechanical force into a proportional electrical signal. Load cell sensors are the most mature technology for the measurement of force; however they have disadvantages as applications advance. They are larger and bulkier than other methods of measuring force, as you can see by its construction shown in Figure 1. Their size makes them impractical in continuum robot applications, which are generally micro-scale.

Piezoelectric Force Sensors

A piezoelectric force sensor (Figure 2) responds to forces through a direct electrical process that eliminates the cost of designing a PCB as part of the device. It’s also smaller for applications like embedded sensors in a manufacturing production line using industrial robots. This technology uses piezoelectricity to create an electrical signal proportional to the force used to compress the device. It’s also a very mature technology and has the advantage of being thin, lightweight, and requires no excitation voltage. (See Comparing Strain Gauges to Piezoelectric Sensors.)

Tactile Sensors

There are many types of tactile sensors. Of these, the force/torque variety is the one we will compare with the other sensors we’ve discussed. A tactile force/torque sensor is a much more sophisticated device than the load cell/strain gauge sensor and piezoelectric force sensor discussed so far. Whereas all are force transducers, the tactile sensor must also be able to measure rotational moments of force (torque) for use in a continuum robot. Therefore, it is ideal for robots that handle objects easily damaged or permanently deformed by excessive force or twisting. [2]

These sensors are yet to have the manipulation skills of a human hand; they are far more primitive. This manipulation technology is still in its infancy, and the control algorithms don’t exist. For now, designers must know the geometry of the grasped object to estimate the constraints that must be put on factors like torsional moments.

Advances in Tactile Sensor Design

The gaps in the technological maturity of tactile sensor design are being addressed via the development of machine learning algorithms. These algorithms gather data on the shape, weight, stiffness and friction coefficient of the objects/surfaces the continuum robot encounters. From this data, the learning algorithms produce a tactile (physical) map of these objects/surfaces. This physical map then trains the robot to exert the appropriate force and torque on these objects as it manipulates them.

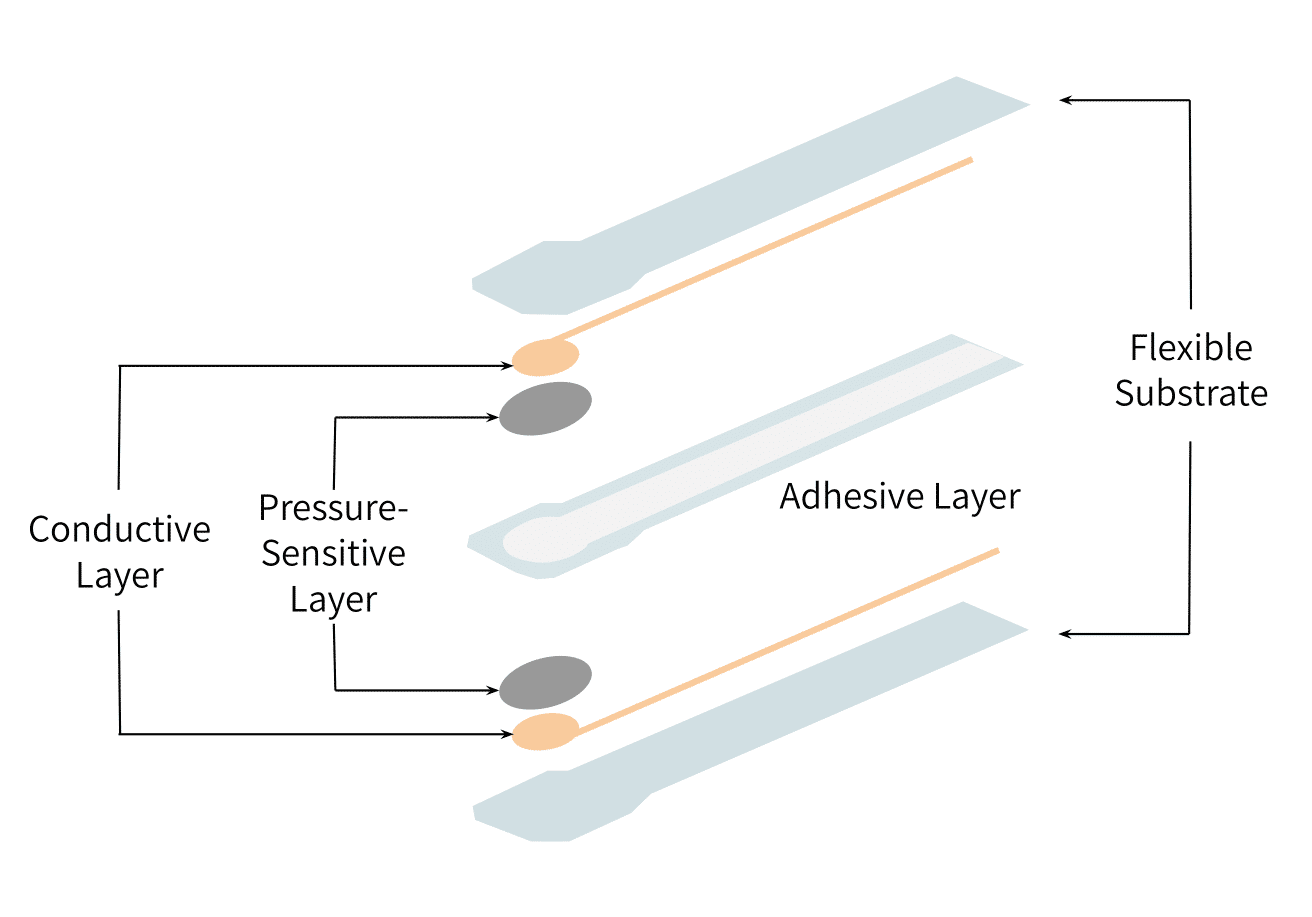

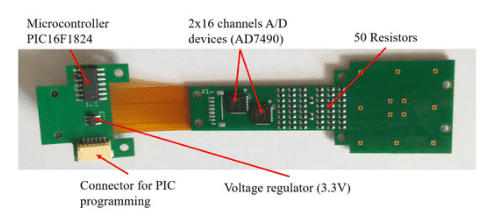

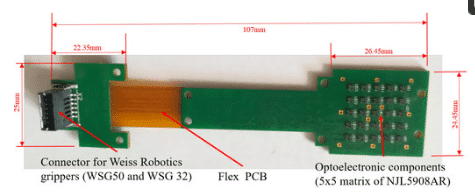

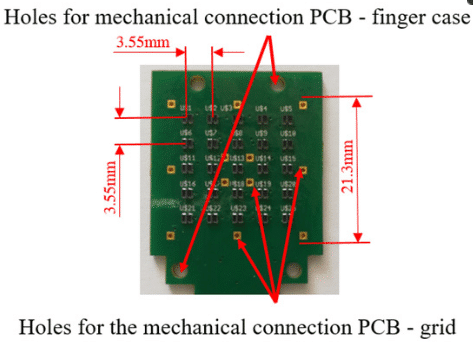

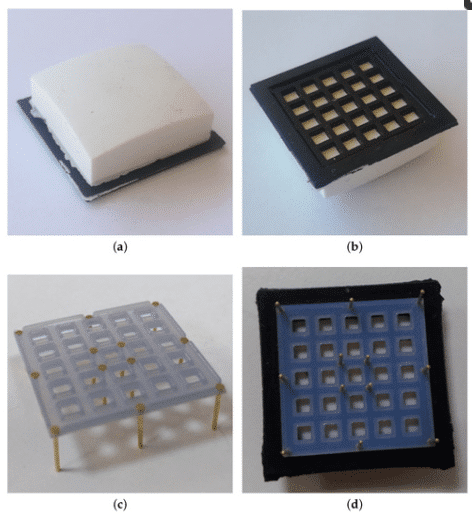

The sensor consists of three components. A PCB (Figure 3) that collects, stores, and analyzes the data and a rigid grid that holds a deformable cap (Figure 4) that generates the data.

Figure 3: Tactile Sensor PCB

Figures 3 and 4 [2] show a miniature force/tactile sensor design that can measure distributed contacts and estimate contact force and torsional moments. It is used for robotic dexterous manipulation tasks. This device’s mechanical interface is a soft silicone pad that can adapt to different object shapes and hold high torsional moments. The sensitive part, the PCB, is based on optoelectronic technology. This technology not only estimates the total contact wrench, but also detects the orientation of the contact surface. And this detection is essential to correctly identify friction force, a relevant quantity in any dexterous manipulation control algorithm.

Interestingly, force sensors are not only components in these devices. They also are useful to test the contact materials in tactile sensors. See our customer case study, Measuring Contact Forces on Soft Materials for Medical Robotics and Other Applications, for an example.

Conclusion

The design of the advanced tactile sensor in this article is only one of several being explored for use in continuum robots. Likewise, the force/torque sensor is only one of several types of sensors in development for this application. However, none of these technologies would be possible without their technological origins in basic load cells. Evolving technologies such as robotics have driven, and will continue to drive, advancements in force sensing instruments for many years.

References

[1] Costanzo, Marco (2019), Design and Calibration of a Force/Tactile Sensor for Dexterous Manipulation, Sensors 19(4), pp 966, https://doi.org/10.3390/s19040966 ; https://www.mdpi.com/1424-8220/19/4/966/htm

[2] Mahvash, Mohsen (2011), Stiffness Control of Surgical Continuum Manipulators, IEEE Transactions on Robotics pp 334-346, DOI 10.1109/TRO.2011.2105410